Complete Body-in-White Manufacturing & Assembly For Automotive Automation Systems

Comau has one of the largest automation networks globally. Our offices and innovation centers are all around the world to support Body-in-white manufacturing needs throughout the complete process.

Our offering extends to:

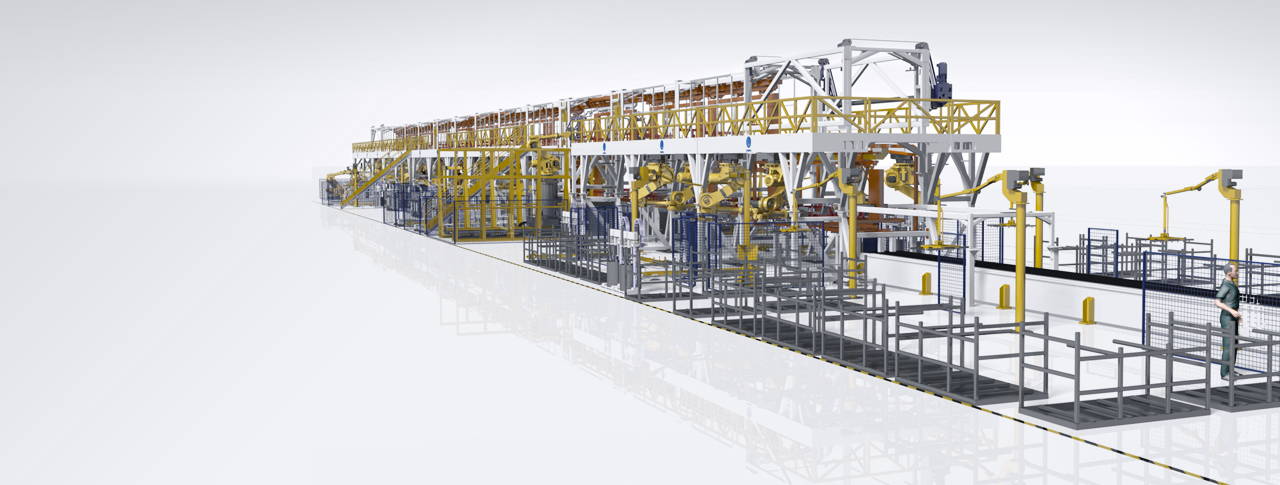

Complete Body-in-white (BIW) manufacturing and assembly systems combined with advanced joining processes for the assembly of car bodies, such as the Open RoboGate framing system. Completely integrated into the factory, our turnkey solutions improve the efficiency of your production process and optimize factory logistics.

From advanced material joining technologies and laser systems for brazing, welding and cutting, to 3D robotic plasma cutting processes and roller hemming (RHEvo), our long-standing tradition of innovation and excellence is without equal.

Welding Guns and Spot-Welding Machines. Accumulating Pallet Conveyors. Break Away End-Effectors. Vision systems and the innovative Recognisense.

Value-driven BIW Manufacturing Solutions

We strive to increase the flexibility and performance of modern body-in-white manufacturing processes with powerful solutions that can evolve in response to developing market needs.

ComauFlex

Developed to streamline high-speed automotive manufacturing, including multi-material vehicles, this production-proven, flexible manufacturing strategy fully responds to the primary market drivers required by today’s car manufacturers: operational flexibility, minimum facility requirements, high volumes and multiple models, along with the possibility of using advanced material joining technologies.

Open RoboGate

Modular, flexible and expandable, the Open RoboGate framing system can handle up to 6 dedicated framing gates and 18 robots for high flexibility, high-speed, high-density operations. Thanks to the use of overhead-mounted inverted robots, it can reduce the overall footprint of the production system while enabling a higher number of joints within the station to guarantee a greater level of geometrical stability and accuracy.

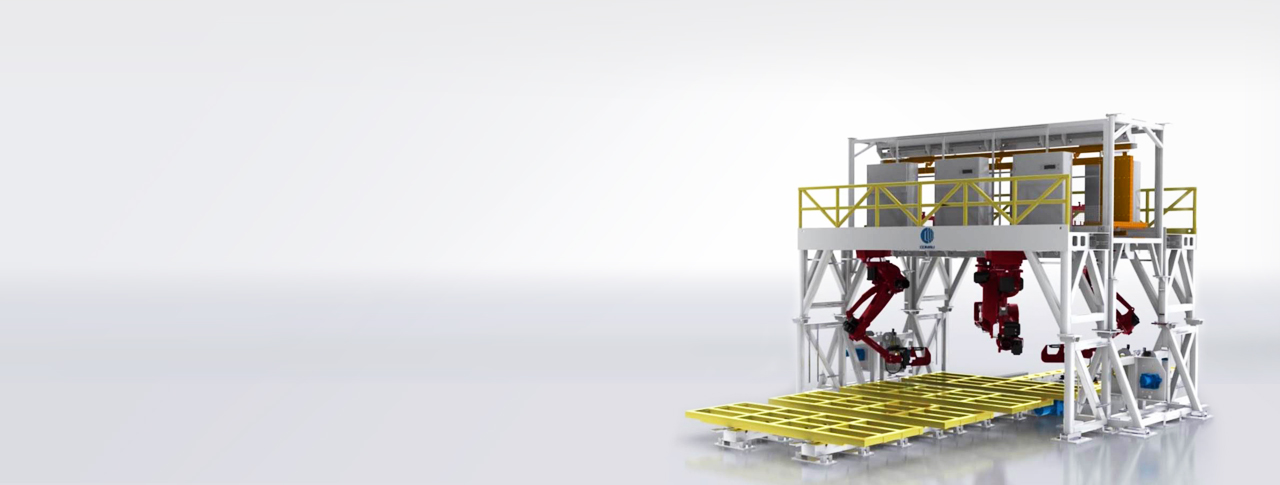

VersaPallet

This high-performance in-line transfer system may just be the automotive industry’s fastest system for moving a geo-pallet through and across the lines. Typically applied from underbody marriage up to body complete, using a fully mechanical geo-pallet that moves the parts down the lines, it can safely speed components through the production process in mere seconds.

VersaRoll

Greater speed, precision and flexibility with capability of changing up to 4 tools within cycle time. Typically used to set the geometry of underbody and body sides, VersaRoll is a closed loop transfer system with integrated logistics capability enabling a streamlined manufacturing process with a single point part feeding.

We get to the heart of the manufacturing process to achieve the desired results. Our Project Execution succeeds through a continuous feedback loop between you and us to conceive, implement and optimize truly innovative solutions.

Fast and Reliable Manufacturing

By creating systems that provide crucial results in terms of productivity, quality, logistics and global integration, we continue to drive innovation. We share the same goals of automakers and other industries:

- Increase competitiveness

- Improve production processes, making them more efficient

- Increase productivity and flexibility maintaining safety and quality standards

Our culture of applying automation to optimize and transform engineering and production processes is what sets us apart. Whether we upgrade your existing facilities, or create new ones, we lead your business into the future.

We Know What Companies Care About Most

Time to market

Operational flexibility

Lowering operating cost

Optimizing processes