Covering your production needs every step of the way

Our solutions are based on leading-edge process technologies, high speed machining, long-term accuracy and reliability. Our integrated approach combines creativity, flexibility and versatility, thus enabling us to develop tailor-made systems based on standard modules that are executed in the context of a close, continuous and strategic cooperation with the customer.

Automotive

Whatever the project or specific constraint, our efficient machining systems adapt to allow Automotive manufacturers of all sizes to reduce launch times while ensuring the highest level of productivity and long-term precision.

Electrification

We bring high configurability, high productivity and long term accuracy to the electric and hybrid vehicle market with field-proven machining solutions for e-drive units, transmissions and more.

Digital solutions

The digitalization of our IoT-enabled machining centers can make your machining processes even more efficient than they already are. This translates to early management of future product changes, a predictive approach to maintenance and quality and enhanced user friendliness, leading to improved overall profitability.

Machining by numbers

2 Innovation centers

6,500 Installed Machines

4 Manufacturing Plants

20 Reference Countries

Backed by decades of innovation and technical excellence, Comau has been a pioneer in Linear Motor technology since the early 90s.

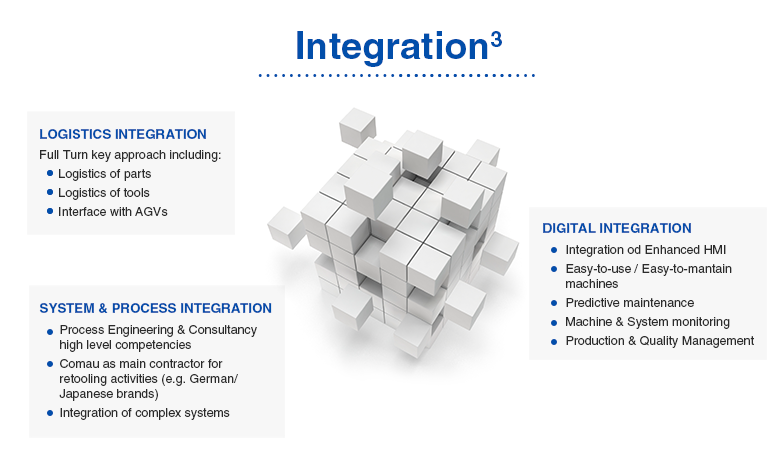

Turnkey systems

Thanks to our longstanding experience in process and equipment integration, we can support your project from its earliest phases to deliver reliable turnkey systems that meet your unique machining needs. Our comprehensive approach to System Integration makes Comau an ideal partner for your entire line.

Customer support

When flexibility and versatility matter, we can adapt our machining systems to meet your specific project requirements, improving your productivity and processes as a result. We can support your project during its entire life cycle by offering comprehensive maintenance services for both Comau and any other equipment brand.

Our service team provides:

- Retooling and relocation

- Refurbishing and safety conformance of existing equipment

- Equipment upgrades to improve performance

- Assistance and service for installed equipment

- Parts replacement

- Training based on customer needs

Standard products

The automotive sector requires increasingly fast, precise and flexible manufacturing processes. To answer these – and many other – operative needs, Comau offers comprehensive product range/portfolio:

- Machining centers

- Assembly & test equipment within machining process/line

- Thermal spray coating

- Material handling

Drive technology: Linear Motors vs Ball Screws

Linear Motors

- Outstanding accuracy achieving the best quality

- Reduced process time

- High dynamic for fast interpolation processing

- Long term stable quality with minimum maintenance requirement

Ball Screws

- Stiffness and accuracy achieving the best quality

- Reduced process time

- High level of flexibility and re-usability

Machining centers

Synonymous with reliability, our powerful machine centers are modular, flexible and highly configurable. So whatever the project or manufacturing constraint, we can help you achieve faster launch times while ensuring the highest level of productivity and long-term precision.

With linear motors and electric spindles, our horizontal machining centers ensure high-speed, dynamic performance and long-term stable accuracy with lower maintenance needs. In addition to offering production solutions for the complete machining of components in different sizes and materials, our machining centers work seamlessly with other automation systems, allowing you to quickly ramp up quantities as needed. What’s more, all components and their manufacturing steps are completely traceable.

Highly Versatile

Industry 4.0 Compatible

Outstanding Dinamics & Accuracy

Thermal spray coating: technology that’s one step ahead

Our innovative coating solutions enable companies to compensate for the tribological differences introduced with aluminum cylinder blocks while increasing their technical performance and lowering costs.