Overcoming Renewable Energy Challenges with Advanced Automation and Robotics

The renewable energy landscape faces pivotal challenges in scaling up to meet global energy demands while reducing environmental impact. From the intermittent nature of solar and wind power to the complexities of hydrogen production, efficiency and reliability are critical. Comau has addressed these challenges with automation technology and advanced robotics. Our innovations empower industries to streamline processes and maximize output, driving forward the adoption of sustainable energy technologies.

Solar Panel Manufacturing and Installation: Precision and Efficiency Redefined

In the solar farm construction, precise installation is essential for cost-effectively harvesting the sun’s power. Comau has collapsed the traditional manufacturing and installation process into a highly efficient, on-site procedure. With its proprietary Comau robotics, lifting equipment and other technology enablers, our temporary mobile factory (Hyperflex) automatically assembles the entire solar blade directly in the photovoltaic field.

By integrating automated technologies into manufacturing and installation processes, we ensure consistent quality and efficiency. This approach not only reduces installation time and costs but also enhances overall system performance, making solar energy more accessible and reliable.

Green Hydrogen Production: Innovating with Robotics

Green Hydrogen has gained relevance in the search for alternative energy sources, as a safe and highly efficient energy carrier, but its production involves complex electrolysis processes. The Comau advanced technology and automation solutions optimize every stage of electrolyzer and fuel cells manufacturing.

Automated systems enable precise control over production parameters, enhancing efficiency and reliability while minimizing environmental impact. By scaling up green hydrogen production through automation, we contribute to a sustainable energy future, meeting growing global demand for carbon-neutral fuels.

Leading the Way in Renewable Energy Automation

By harnessing the power of automation, we enable industries to achieve greater efficiency, reliability, and sustainability in their operations. Explore how our tailored solutions can transform your approach to renewable energy production and installation, driving progress towards a cleaner, greener future.

Comau is in the unique position to integrate advanced automation and robotics into renewable energy applications. Our solutions not only overcome current challenges but also pave the way for future innovations.

The Hydrogen Value Chain

| Primary Energy | Conversion & Processing | Storage, Transportation & Distribution | Final Energy Demand |

| The value chain begins with the generation of renewable energy from renewables (solar, wind, hydropower). This energy is crucial as it will power the electrolysis process later on. | Electrolyzers split water into hydrogen and oxygen. The hydrogen produced is considered green if the electricity used is from renewable sources. | Once produced, the hydrogen is typically compressed and stored in tanks. Hydrogen can be transported in various ways, including pipelines, trucks, or ships. Distribution involves delivering hydrogen to end-users, e.g.: refueling stations. | The final stage of the value chain involves the use of hydrogen in different sectors. This can include using Hydrogen as a fuel for transportation, feedstock for industrial processes, or a source of clean energy in power generation. |

By integrating its advanced technology and automation expertise to manage the assembly and production of fuel cells and electrolyzers, Comau is helping companies scale-up production volumes.

More importantly, its field proven solutions ensure absolute quality and full traceability throughout the high-precision manufacturing process.

Decoding the Technology Roadmap

Fuel cells combine hydrogen and air to produce electricity, emitting only water and heat as by products. Electrolyzers do the opposite, breaking water into hydrogen and oxygen using electricity.

Both are considered to be highly efficient energy sources and market forecasts suggest that the increasing demand for green hydrogen will boost the demand for electrolyzers from an estimated 120 MW installed in 2020 to more than 20 GW in 2030.

Here at Comau, we are automating the production of electrolyzers and fuel cells to support the creation of zero-emission green hydrogen. To do so, we work side-by-side with our customers to manage the entire industrial process life cycle, from conceptual engineering to manufacturing and support services with the goal of making a better electrolyzer, or fuel cell, at a lower cost.

In fact, Comau automation can help manufacturers reduce costs by up to 20%.

Automated Manufacturing Made Easy

Comau’s expertise in automating traditionally manual manufacturing processes extends to hydrogen and renewable energy. Backed by our Design for Manufacturing and Assembly approach, which includes Design for Automation, we employ a synergistic method of designing the manufacturing process in tandem with the product itself. From start to finish, we help you evaluate opportunities, automate key processes and upskill your workforce.

- Consultancy: manufacturing concept & simultaneous engineering, DFMEA¹, business case support

- Validation: in-house lab testing, pilot development

- Turnkey supply: scalable and seamless solutions

- Digitalization: traceability, quality inspection, line monitoring and simulation

- Training & Support: robotics supervision and management, technical training and after sales services

¹Design Failure Mode and Effects Analysis

Full Service Partner

Speeding the world’s annual hydrogen production capacity is just one benefit of automation; others include increased precision and the reduced burden of cleanroom security measures.

As a full service partner, Comau supports its customers along their hydrogen production and utilization journey regardless of the underlying fuel cell or electrolyzer technology.

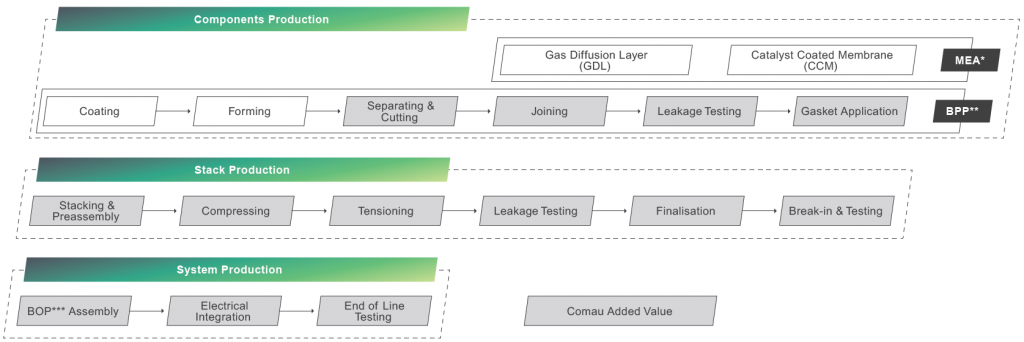

Our proprietary solutions portfolio is designed to automate key process steps including cell preparation and stacking, leak testing and more. The following boxes in grey represent the areas where Comau leverages the full potential of automation. Visit the download section below and access the brochure.

*MEA: Membrane Electrode Assembly

**BPP: Bipolar Plate

***BOP: Balance of Plant

In addition, by supporting customers with our Simultaneous Engineering approach, we can help them design their products in a way that will be easier and more cost effective when assembling them with automation.