Fast set-up with zero engineering design hours

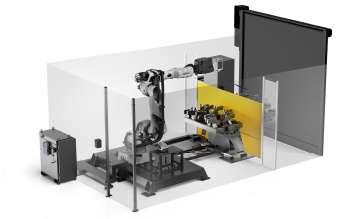

Comau’s Zero Design manufacturing approach lets companies of all sizes leverage standardized, pre-engineered cells to simplify automation without sacrificing precision or performance. Comau’s interchangeable design structure guarantees easy reuse and repurposing when production requirements change, which can be as simple as changing the auxiliary equipment.

Protect your investment with built-in flexibility

With a modular structure and easily substitutable tools and end-effectors, each Zero Design cell forms the base for multiple different robotic set-ups, letting you perform diverse applications with the same cell unit. What’s more, production can be ramped up or down without the need for costly structural changes. And because the cells are highly versatile, you can personalize your set-up while ensuring future scalability.

Cutting-edge Automation

Thanks to proven expertise in automation, digitalization and electrification, Comau is able to provide best-in-class systems based upon standardized robotic cells that are fully tested, validated and functional before arriving at the customer’s site.

Better Time

to Market

Zero design manufacturing allows organizations to quickly respond to changes in customer demand without lengthy engineering design time, which can significantly reduce the time and cost of deploying new applications.

Real-time Analysis and Control

From real-time performance and status analysis to the automated traceability of parts and quality of output, comprehensive cell digitalization lets you control parameters and immediately correct process or material variations in real-time.

Top benefits of Comau’s Modular Standard Cells

eBook

Optimizing Production with Modular Standard Cells

The case for simplifying automation without sacrificing precision or performance.