MI.RA/OnePicker: Intelligent Vision-assisted Picking

Designed to autonomously pick miscellaneous objects from the same bin without relying on CAD-based assistance (vision-assisted picking) or prior information about their size, shape, color or characteristics, MI.RA/OnePicker is the smart way to increase productivity, worker safety and overall efficiency.

Comau’s new AI-backed piece picking solution pairs state-of-the-art vision technology with advanced sensors to detect and localize randomly displaced objects and proactively determine the most effective way to empty the bin.

And because MI.RA/OnePicker ensures unparalleled precision and productivity, it reduces the need for manual and repetitive operations while saving time and costs.

Vision-assited Picking: Application Trends

Leveraging its proprietary automation and machine learning paradigms, Comau is increasingly able to automate complex piece picking operations.

It’s a market that is expected to reach $1.2B by 2025 with a compound annual growth rate of 76% (2019-2025)¹, driven largely by the strong growth of industries such as warehousing, machine tending and manufacturing, among others.

MI.RA/OnePicker is designed to address these markets and is the result of Comau’s systems-based approach to flexible automation, which allows the company to offer powerful turn-key solutions using the most suitable equipment for the needs of each specific project.

For example, the smart functionality of Comau’s newest MI.RA solution is ideal for pick&place, kitting, sorting, warehouse, e-commerce and machine tending applications.

¹ Based on internal estimates and supporting market research

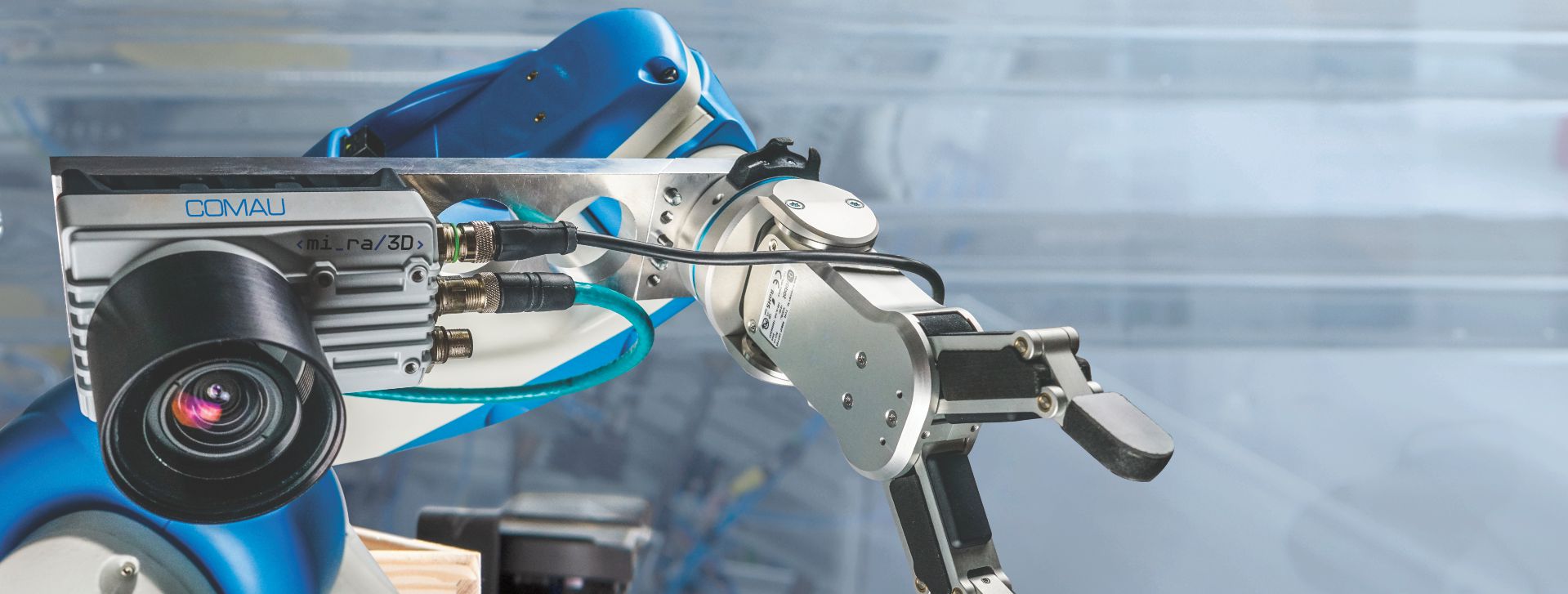

Vision System for 3D Robot Guidance

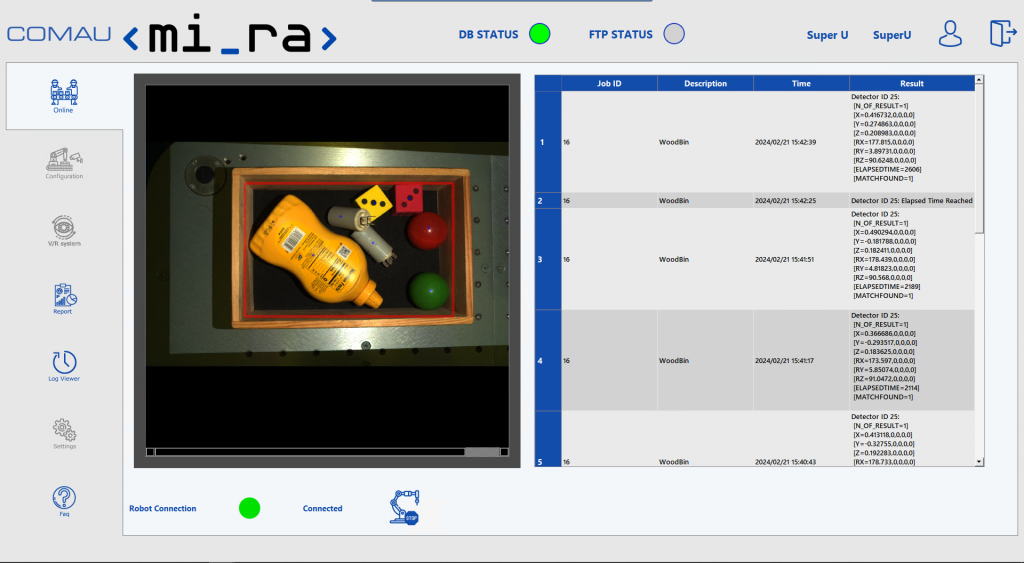

| • Advanced path planning • User-friendly interface • Mutiple cameras support • Scalable • TCP/IP Communications | • No CAD needed • Manage multiple objects inside the same bin • Works with vaccum-based grippers |

Applications

Kitting

Sorting

E-commerce

Intuitive Flexibility

Thanks to a highly intuitive configuration page, it is easy to set up the bin environment and specify the necessary parameters for the integrated artificial intelligence algorithms to achieve an ideal balance between computational speed and accuracy.

Leveraging user-defined 3D models of the bin and the robot, MI.RA/OnePicker guarantees efficient path planning and collision-free movements in complete safety while ensuring optimal piece picking performance by the robot.

Sustainable Upstream Logistics

By eliminating unsustainable manual sorting tasks and repetitive operations, MI.RA/OnePicker enhances operator welfare and well-being.

Not only does the smart piece picking solution easily handle mixed and disarranged products inside one or more bins (instead of placed in an orderly manner), it reduces upstream process times. Since the products can now be dumped into the bins instead of being singularized, MI.RA/OnePicker also facilitates simplified logistic flows.

Hardware Agnostic

MI.RA/OnePicker is fully adaptable to any brand of commercial robot, customized bin or customized gripper. It also supports two types of sensors: a stereoscopic system or structured light cameras.

And with reduced acquisition times, they have virtually no impact on the manipulator or the automated gripping process cycle time.

Collaborative Piece Picking Robot

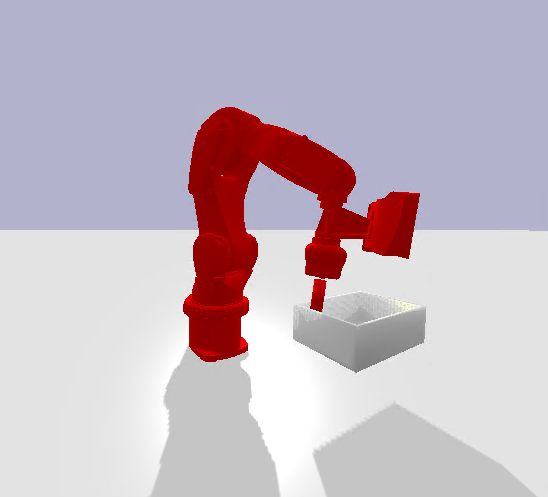

MIRA One Picker can also be provided in an all-in-one Solution, combined with Comau’s Racer-5 COBOT, a 6-axis articulated robot that delivers speed, accuracy, repeatability and certified collaboration safety without cages.

In addition to fully leveraging Comau’s factory-proven expertise in robotic automation, Racer-5 COBOT can automatically switch from industrial mode to collaborative mode.

Because the compact COBOT works at full speeds when human operators are not in the vicinity and at collaborative speeds when they are, productivity remains high and cycle times are reduced.

Vision-assisted Picking System

Designed to unleash the full potential of multi-box piece-picking, the compact and lightweight robot vision guidance system can be installed on even the smallest collaborative robots without limiting its reachability inside the bins.

Furthermore, with the RGB-D input image, the objects’picking pose is calculated in less than 3 seconds!

View more automated vision-based solutions

Comau supports clients in the development of smart and flexible collaborative and vision-based technologies backed on advanced robotics, addressing the most complex challenges and production requirements.