UM NOVO CONCEITO NA INSTALAÇÃO AUTOMÁTICA SUSTENTÁVEL DE PAINÉIS SOLARES IN-LOCO

• Tecnologia móvel patenteada da Comau oferece melhor segurança e sustentabilidade com a instalação automática de rastreadores solares diretamente no campo fotovoltaico

• Com uma taxa de instalação de até 30% de módulos a mais por hora e por operador em comparação com os processos padrão, o Hyperflex facilita a construção mais rápida da planta e a subsequente produção de energia renovável

• Tempo de comercialização até 25% mais rápido para novas fábricas, com uma economia média de 35% no preço por painel

• Seu design flexível permite aplicar diferentes tipos de rastreadores e painéis, adaptando-se facilmente às necessidades específicas de diferentes fornecedores de energia

Grugliasco (Turim), 27 de junho de 2023

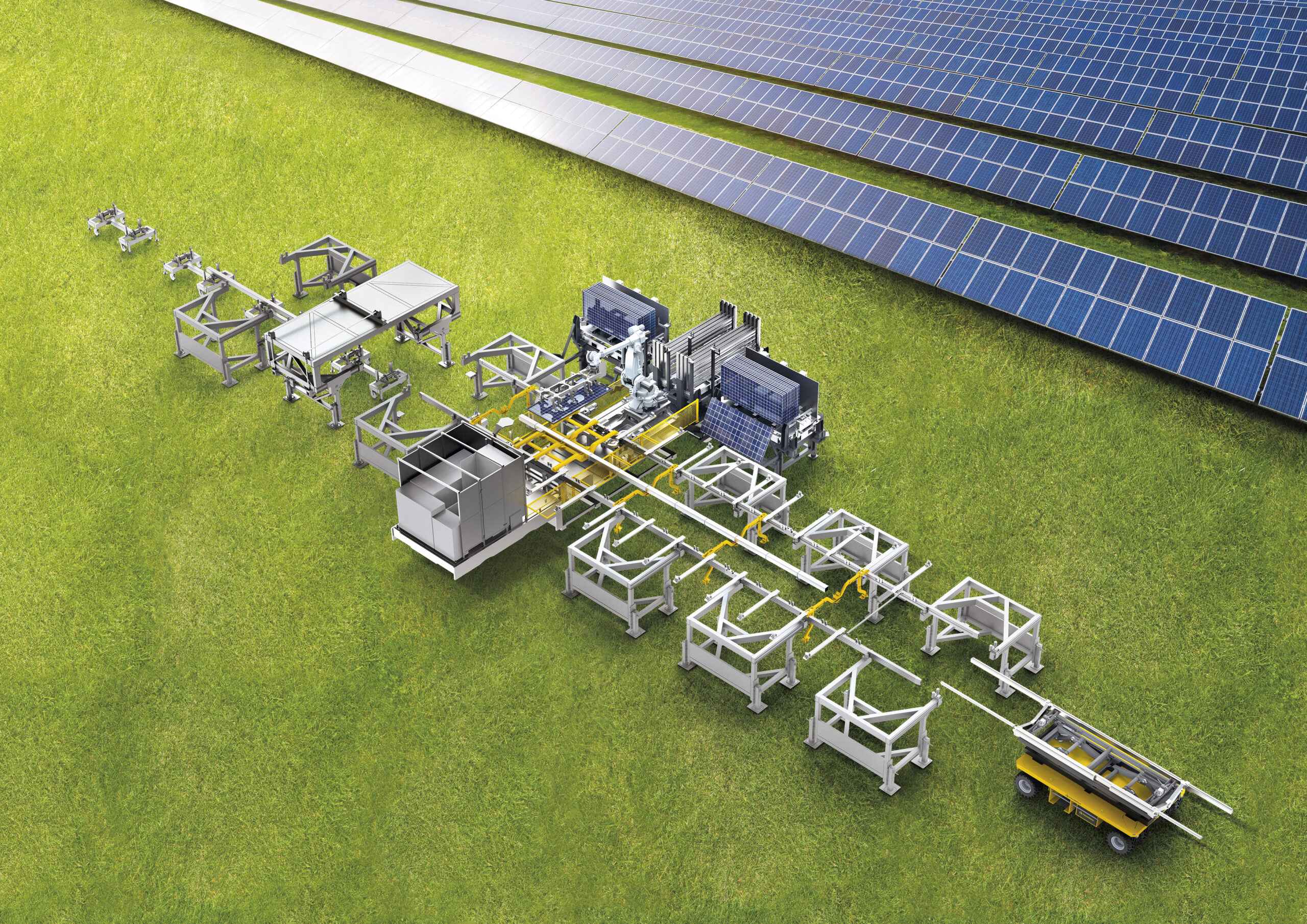

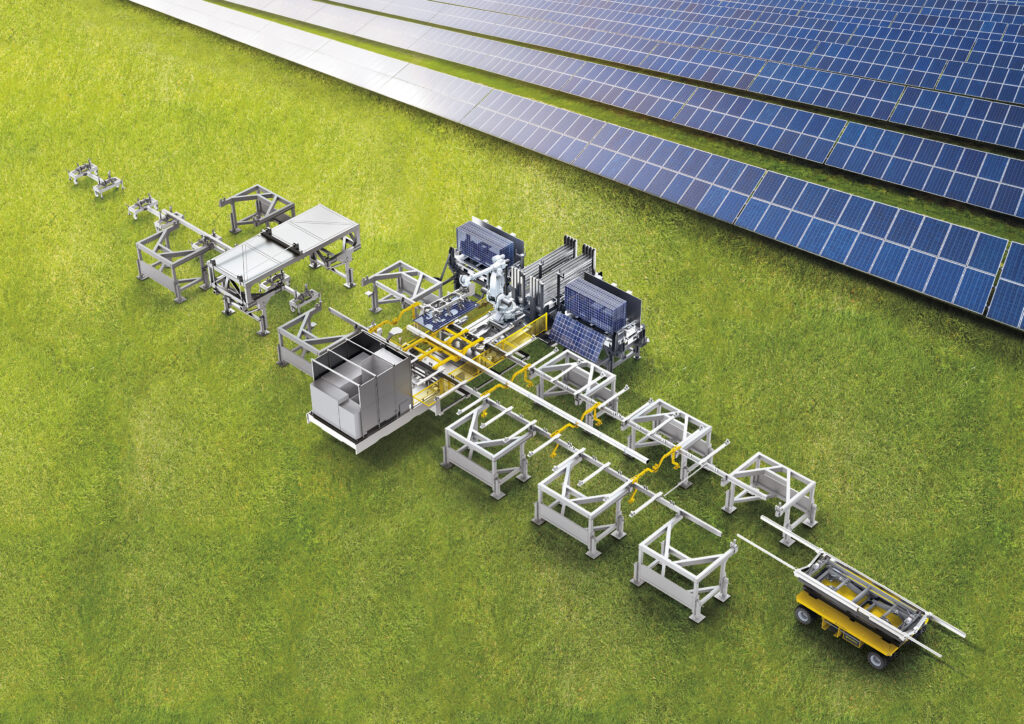

A Comau estreia sua fábrica móvel patenteada Hyperflex, um novo paradigma na implantação de painéis solares que facilita a construção mais rápida de instalações fotovoltaicas, reduzindo de até 25% o tempo de comercialização em novas instalações. Projetado internamente e com robótica, equipamentos de elevação e outros recursos tecnológicos de propriedade da Comau, o Hyperflex monta automaticamente todo o painel solar, que pode medir até 48 m2, diretamente no campo fotovoltaico. Desta forma, a fábrica móvel temporária robotizada reduz os custos operacionais gerais e permite aumentar o bem-estar do operador, a qualidade do processo e a produtividade geral ao expandir uma planta existente ou instalar uma nova. Além disso, o design flexível do Hyperflex pode acomodar diferentes tipos de rastreadores e painéis, adaptando-se facilmente às necessidades específicas de diferentes fornecedores de energia.

Com o Hyperflex, a Comau abandona o processo tradicional de fabricação e instalação, e o substitui por um procedimento in-loco, altamente eficiente, que fabrica o tubo de torque, a viga transversal e o módulo FV em uma única estação de produção robotizada. Graças a associação otimizada de processos manuais e automatizados, em que operadores trabalham ao lado do robô, com total segurança, graças a técnicas avançadas de escaneamento a laser, o HyperFlex facilita a produção de energia verde, melhorando ao mesmo tempo as condições de trabalho dos operadores. Com uma taxa de instalação de até 30% a mais de painéis por hora por operador em comparação com os processos padrão, o Hyperflex permite reduzir de até 25% o tempo de comercialização para novas plantas, com uma economia média de 35% no preço por painel. A solução robótica pode, portanto, desempenhar um papel decisivo para ajudar na implantação da energia renovável.

Por se tratar de uma fábrica móvel temporária, toda a solução é alojada no interior de um semi-reboque que pode ser facilmente enviado de uma usina solar a outra. Além de garantir o controle centralizado de todo o processo e criar um novo fluxo de logística KM 0 diretamente no campo, Hyperflex melhora a eficiência e reduz o consumo geral de energia. le também melhora a cadeia de valor fotovoltaica ao nível da planta e permite que os operadores em campo desempenhem um papel fundamental no controle de qualidade e no gerenciamento de processos. Além disso, a industrialização desta solução da Comau contribuirá para o progresso da conversão energética. E como o design flexível se adapta facilmente a diferentes tipos de rastreadores e painéis, o sistema Hyperflex pode ser personalizado para atender às necessidades específicas de diferentes fornecedores de energia.

Melhor qualidade e custos gerais mais baixos na instalação dos painéis solares

“Reduzir os custos da instalação do parque solar é de suma importância e um fator chave para atingir as metas de emissão líquida zero do mundo”, disse Nicole Clement, diretora de soluções avançadas de automação da Comau. “Com base em estimativas internas e o suporte de pesquisas de mercado, acreditamos que a instalação global de painéis fotovoltaicos para parques solares terá uma CAGR de 10% entre 2022 e 2030. O Hyperflex está bem posicionado para acelerar a implantação de novas instalações, garantindo melhor qualidade, maior eficiência e custos gerais mais baixos, ajudando nossos clientes a contribuir para tornar a energia solar sustentável uma realidade.”

Nicole Clement, Chief of Advanced Automation Solutions at Comau

Downloads

Sobre a Comau

A Comau, uma empresa Stellantis, é líder mundial no fornecimento de soluções sustentáveis de automação avançada Com 50 anos de experiência e presença global, a Comau ajuda empresas de todos os portes em praticamente qualquer indústria a aproveitar os benefícios da automação.

Apoiado por um compromisso contínuo com o projeto e desenvolvimento de tecnologias inovadoras e fáceis de usar, seu portfólio inclui produtos e sistemas para a fabricação de veículos, com uma forte presença em e-Mobility, bem como uma robótica avançada e soluções digitais para abordar mercados em rápido crescimento nos setores industriais.

A oferta da empresa também se estende à gestão de projetos e consultoria. Através das atividades de treinamento organizadas por sua Academia, a Comau tem o compromisso de promover o conhecimento técnico e

gerencial necessário para enfrentar os desafios relacionados à automação e

aproveitar as oportunidades de um mercado em constante mudança.

Com sede em Turim, Itália, a Comau tem uma rede internacional de 5 centros de inovação, 5 centros digitais e 12 fábricas que abrangem 13 países e empregam 3.700 pessoas. Com sua ampla rede de distribuidores e parceiros, a empresa é capaz de responder rapidamente às necessidades dos clientes, independentemente de onde estejam localizados em todo o mundo.

Entre em contato

Você pode entrar em contato com nossa Assessoria de Imprensa e os gestores da área de Mídia,

inserindo seus dados de contato.