Electrolyzers and Fuel Cells Manufacturing: Powering Decarbonization

Hydrogen is a safe and highly efficient energy carrier. It is also a reliable, zero-emission power source that can fuel passenger and industrial vehicles, in addition to other applications.

This places hydrogen in an ideal position to boost the adoption of renewables worldwide, which will subsequently help tackle multiple critical energy challenges. Which is why Comau is leading the efforts to make automated assembly for fuel cells and electrolyzers a reality.

Click here to learn more about the hydrogen manufacturing value chain.

Hydrogen Automation Solutions

For both hydrogen production and utilization, Comau supports customers in their fuel cell manufacturing and electrolyzer manufacturing journeys.

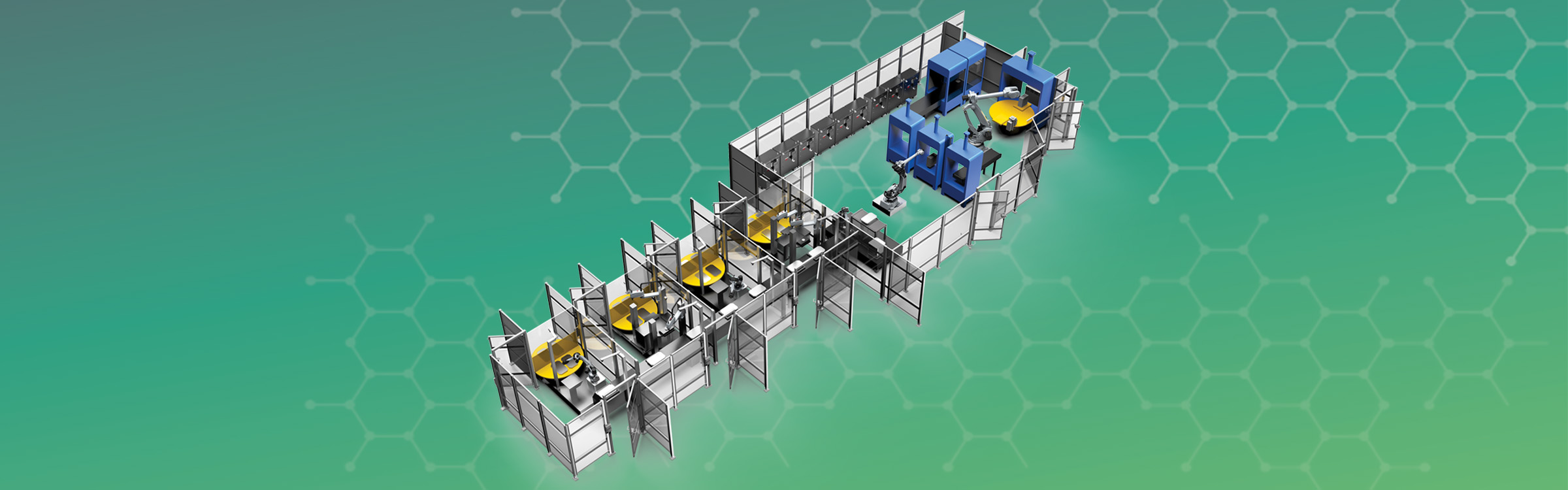

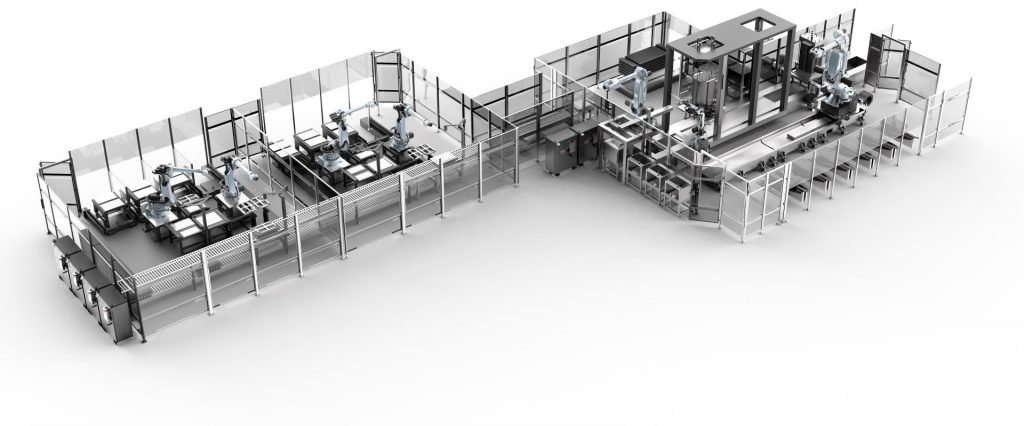

For electrolyzers and fuel cells, PEM, alkaline, AEM or SOFC, Comau offers automated hydrogen production solutions for stacking, testing, BoP assembly and more.

Comau Offering

Fuel Cell Manufacturing

From a thorough product and process analysis to the final stages of budgeting and planning, our automated fuel cell assembly offer ensures efficient project reshaping, ergonomic and quality analysis, concept layout, station design, control layout, simulation, and validation.

Backed by a Simultaneous Engineering approach, we bring your automation vision to life with precision and expertise.

Click the features below to learn more:

Electrolyzer Manufacturing

Click the features below to learn more:

Meet our Team

Stefano Pesce

Head of Business Development

stefano.pesce@comau.com

+39 3358049809

Lorenzo Montigny

Senior Business Developer

lorenzo.montigny@comau.com

+33 (0)6 45 06 96 99

Lucrezia Morabito

Product and Solution Manager

lucrezia.morabito@comau.com

+39 3346706561

Why Choose Comau for Hydrogen Automation?

Disruptive Approach

Our Simultaneous Engineering process ensures efficiency from product analysis to final budgeting and planning. By integrating ergonomic and quality assessments, with the concept layout, station design, control layout, simulation, and validation, we work alongside our customers to bring their automation visions to life.

In-House Validation

Comau’s in-house lab tests and demonstrator cells validate your systems, ensuring they meet the highest standards before full-scale implementation.

Turnkey Supply

Comau offers scalable, seamless cell and stack assembly line solutions, integrating robotics and equipment from all brands. Our longstanding robotics expertise and systems integration approach let you further benefit from the inherent processes and performance efficiencies of working with a single turnkey supplier.

Training & Support

We provide expert robotics supervision and management alongside dedicated technical training to ensure your team operates with confidence and efficiency.

A Global Spirit with a Local Presence

With a strong international network and decades of PMI project management experience, Comau offers trusted, localized support wherever your operations are based. We collaborate closely with your team to ensure smooth, high-performance project execution.

Manufacturing Excellence

Today’s fuel cell manufacturing and electrolyzer assembly scenarios increasingly require full process traceability and may or may not necessitate adherence to clean room standards. Cell testing procedures are also extensive and cover both leaks and electrical operations.

Here’s where Comau’s 50+ years of automation expertise gives us a leading edge. We make sure that every unit undergoes rigorous leak testing, validating its integrity and performance.

Our complete family of robots, and advanced gripping and vision systems enable the effective automation of stack and system production.

Comau’s consultancy services further provide manufacturing concepts, DFMEA, and business case support to successfully address the individual characteristics of each project.

More importantly, our standard automation cells ensure easy set-up with zero engineering design hours to ramp-up production in the fastest and most cost-effective way possible – without sacrificing advanced functionality or future scalability.

Steadfast Commitment to Proven Results in the Hydrogen Field

Enabling hydrogen manufacturing and deployment is a priority at Comau. Our very first hydrogen fuel cell project featured a proprietary high-speed, high-precision multi-axis stacking technology that can simultaneously manage the pole piece pick-up, code scanning, secondary positioning, and shell loading within 4 seconds.

Similarly, we are actively applying our expertise on multiple fuel cell and electrolyzer projects around the world, including solutions for light and heavy-duty vehicles.

When it comes to increasing production volumes while lowering the cost of fuel cell and electrolyzer manufacturing, Comau is your automation partner of choice.

Contact Comau

Discover how Comau can help you enable alternative energy sources.

You can get in touch with our Sales area by entering your contact information.