Discovering the Comau Educational Robot

e.DO robot has 6 powered axes and a maximum payload of 1kg and can perform all kinds of tasks, from simple movements in space to pick & place operations like lifting, moving, manipulating and rotating parts right up to complex automated procedures.

Thanks to the support of innovative teaching and learning tools, e.DO makes educational projects far more stimulating and exciting.

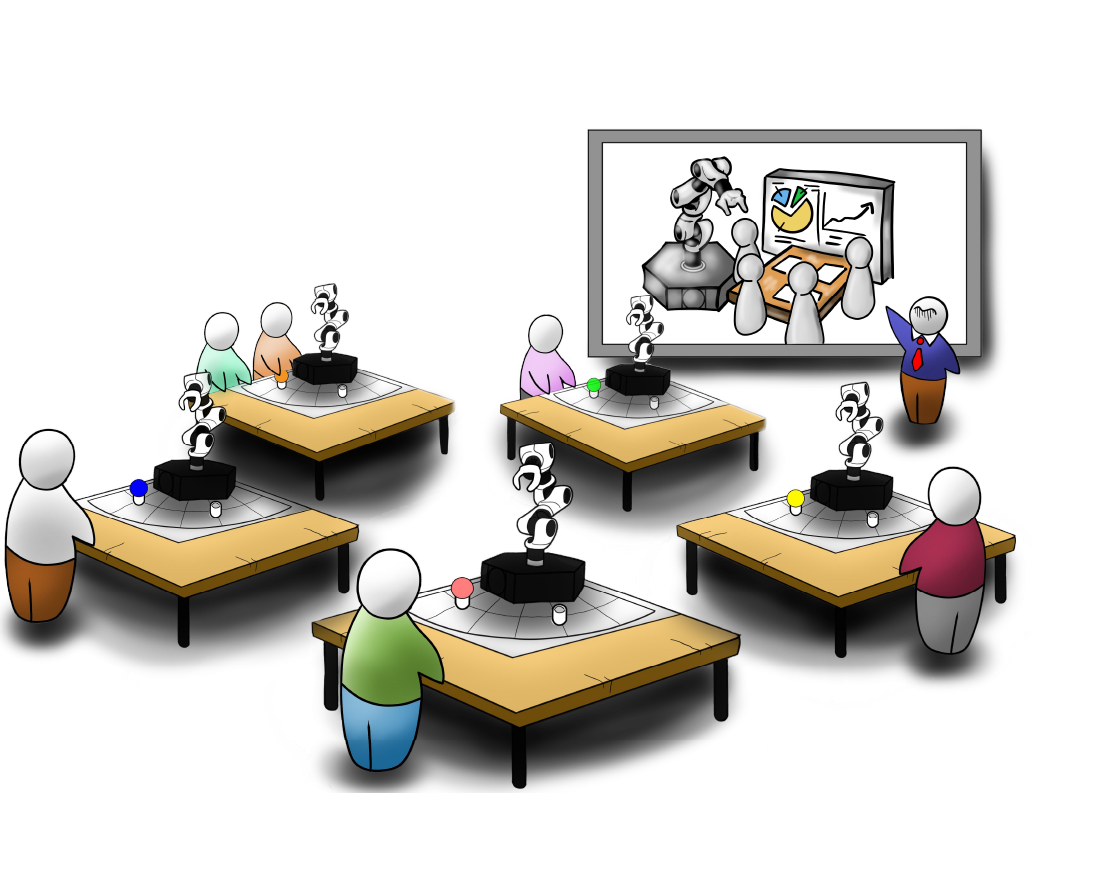

Want to try using e.DO for education and training?

Discover the educational possibilities that e.DO offers you thanks to innovative and engaging tools designed for students, teachers and families

Discover our Educational Products

Tools, educational programs and laboratories integrated with the e.DO Experience, to guide and accompany both teachers and students in the learning paths with e.DO Robot and e.DO Cube.

Activity Cards

Didactic material to assist students and teachers during educational experiences conducted with the e.DO robot and e.DO Cube

DidAPPs

Interactive learning paths, developed by Comau to guide teachers and students in every phase of the learning path with

e.DO robot and e.DO Cube

Training Packages

complete, turn-key teaching projects, designed for presentation in conjunction with an e.DO robot and e.DO Cube

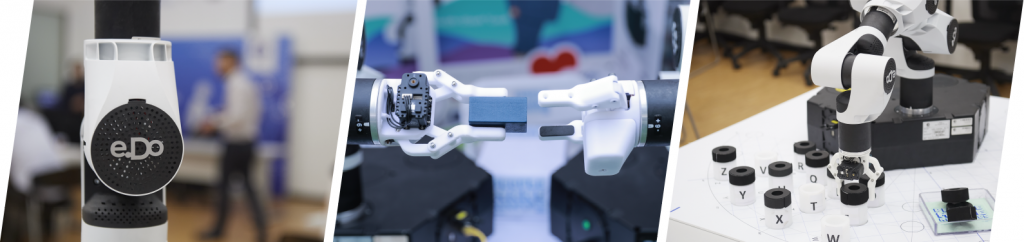

Combining Technoologies to innovative philosophy

e.DO combines all the technological know-how of Comau – worldwide leader in industrial automation –

with a complete open-source philosophy. Thanks to open control logic and a native ROS, e.DO

gives users complete freedom to create and run programs and applications.

Main features

Open Platform

Since e.DO works thanks to ROS (Robot Operating System, ros.org), robot enthusiasts can program e.DO with a wide range of languages such as C / C ++, Python, Java and interact with any ROS compatible hardware or software component.

ROS is also used by students of all ages – from children interacting with robots in museum exhibits to graduate students learning the latest solutions to common robotics problems.

Hardware & Software Architecture

Inside the elegant hexagonal base, e.DO contains a Raspberry Pi motherboard with an operating system based on Linux.

The e.DO development environment allows advanced users to directly enter the integrated control system and improve it; this system provides e.DO with the intelligence and flexibility to create complex movements, perform advanced sequences and automate real-world processes.

Certificates

e.DO is considered a “machine” according to the definition of the Machinery Directive 2006/42 / EC and a “Robot for Personal Care” according to the EN ISO 13482: 2014.

This means that e.DO can be used safely without barriers by anyone over 8 years old (with adult supervision).