Digital Innovation

Comau’s digital expertise has been crucial for numerous European projects over the years. From plug-and-play platforms to Machine Learning, digital innovation is essential for the development of new production paradigms in an increasingly data-driven world.

openZDM – Open Platform for Realizing Zero Defects in Cyber Physical Manufacturing

Country/Business: Italy/Digital Innovation

Main Objectives:

openZDM is an initiative that will develop and demonstrate an open platform designed to realise Zero Defect Manufacturing, in order to deliver high-quality products minimizing waste and energy consumption and maximizing process efficiency. The platform integrates advanced ICT solutions and innovative non-destructive testing, setting the foundations for a solution applicable to a large variety of manufacturing industries. openZDM Project includes prototyping, testing and demonstration in an operational environment, identification and detailed description of requirements, industrial use cases, data sources and reference architecture. Through five industrial pilots in real-life operational conditions (demonstrating TRL 7) from different industrial sectors, openZDM will test and finalise the technological tools and facilitate the adoption for the new innovative platform solution.

- Partners

- LMS, COMAU, VDL, VOLKSWAGEN AUTOEUROPA, SONAE, VIDRALA, INTRASOFT, U-SENSE, AIMEN, INDUCTION, HABBER TEC, MSI, F6S, TECNALIA, UNIVPM, IPB, UNIV. PORTO, APTIV

Project links: openzdm

ALICIA – Assembly Lines In CIrculAtion – smart digital tools for the sustainable, human-centric and resilient use of production resources

Country/Business: Italy/Digital Innovation

Main Objectives:

More than half of industrial robots and other production assets are usually replaced and taken out of operation prematurely. The ALICIA project will reverse this trend and contribute to the creation of a circular economy, designing a circular manufacturing ecosystem so that production resources will be traded and reused to their maximum utility in between factories in Europe. The circular manufacturing approach will be tested in two real industrial environments. The innovations behind ALICIA include a machine-readable ontology for mapping factory owner requirements and an AI-matchmaking engine for combining incumbent factory assets with second-hand assets coming from the ALICIA online marketplace.

- Partners

- TUM, COMAU, TU GRAZ, MTS, CONTI, ECI MECHATRONICS, IMT, YAGHMA, INTRASOFT, LMS, DIN, SURPLEX

Project links: Assembly Lines In CIrculAtion

DIGICOR – Decentralized Agile Coordination Across Supply Chains

Country/Business: Italy/Digital Innovation

Main Objectives:

DIGICOR addresses the need of European manufacturers to increase their competitive advantage in an increasingly data-driven economy. The project featured the development of an open, collaborative platform along with tools and services for the setup and coordination of production networks where smaller yet innovative companies (SMEs) can be integrated into the supply chain of large manufacturers (OEMs). The platform aims to provide services with the creation of a marketplace where the collaborating partners can plan and control the production process, logistics and risk management. All of it will be seamlessly connected to the automated solutions of cyber-physical systems, Internet of Things (IoT) objects and real-time data sources across the network.

- Partners

- COMAU (IT), AIRBUS DEFENSE AND SPACE (D), HANSE (D), CONTROL 2K (UK), CERTICON (CZ), SINGULARLOGIC (GR), ICE (UK), ALMENDE (NL), UNI. MANCHESTER (UK), CVUT (CZ), FORTISS (D)

Project links: cordis

SERENA – VerSatilE plug-and-play platform enabling remote pREdictive mainteNAnce

Country/Business: Italy/Digital Innovation

Main Objectives:

The SERENA system aims to provide a versatile platform that can put the latest breakthroughs in remote predictive maintenance to use in line with the needs of European manufacturers. It was applied in 5 different use cases in key industries like Metrological Engineering, Steel Parts and Elevators production, White Goods and Robotics. By considering companies’ need for versatility, transferability, remote monitoring and control, the project seeks to apply advanced data analytics, A.I. monitoring and hybrid methods to predict any potential equipment failure and improve process-related parameters. Thanks to its plug-and-play architecture, SERENA also offers accessible Human Machine Interfaces (HMIs) that allow human operators remote access in the cloud and manage gathered data of machines’ status with Augmented Reality devices. Assisted by edge computing, the platform can discern between smart and big data for proper use. The project is expected to reduce failure rates, repaired-caused downtime and unplanned plant outages, thus increasing in-service efficiency by 10%.

- Partners

- COMAU (IT), Finn-Power (FI), VDL WEWELER (NL), WHIRLPOOL (I), KONE (FI), ENGINEERING (I), OCULAVIS (D), SynArea (I), DELL EMC (IE), LMS (GR), FhG-IPT (D), VTT (FI), TRIMEK (E), POLITO (I)

Project links: serena-project

MUSKETEER – Machine learning to augment shared knowledge in federated privacy-preserving scenarios

Country/Business: Italy/Digital Innovation

Main Objectives:

The main goal of MUSKETEER is to offer a secure European data sharing environment that is both cross-domain and scalable. The creation of such a federated machine learning platform focuses on preserving privacy, with data being stored in different locations with dissimilar privacy constraints but shared securely, thus ensuring a more robust security against internal and external threats. Comau, in collaboration with various partners, is currently validating the project in two distinct industrial scenarios like Smart Manufacturing and Healthcare. Once validation will be done, MUSKETEER will be applied to other fields, guaranteeing high confidentiality, trustworthiness and scalability across different domains. Its impact can lead to a more rewarding model of the data economy that is capable of fairly monetizing datasets relative to their real value.

- Partners

- COMAU (IT), TREELOGIC (ES), IBM (IE), IMPERIAL COLLEGE (UK), ENGINEERING (IT), UNIV. CARLOS III (E), IDSA (D), KUL (B), FCA ITEM (IT), BIOTRONICS (UK), HYGEIA (GR)

MADEin4 – Metrology Advances for Digitized ECS industry 4.0

Country/Business: Italy/Digital Innovation-Robotics

Main Objectives:

MADEin4 is a comprehensive framework that aims to develop next generation Electronic Components and Systems (ECS) Metrology tools, Artificial Intelligence and Machine Learning methods and applications to support Industry 4.0 high-volume production for the semiconductor manufacturing industry. Metrology is crucial for the manufacturing process of Integrated Circuits (IC), since it often relies on High-Performance computing to measure silicon wafers down to a nanometric scale. The project will address the challenges faced in IC fabs by developing tools for Cyber Physical Systems that focus on higher productivity using edge computing, plus Smart Manufacturing Standards that gather real-time data in order to enhance efficiency and perform predictive maintenance activities whenever needed. MADEin4 is expected to help European ECS and Automotive industries become more competitive.

- Partners

- APPLIED MATERIALS ISRAEL, COMAU, ST MICROELECTRONICS, FCA, POLITO, CNR + Other about 40 partners

Project links: industry4e effra ecsel

5GROWTH – 5G-enabled Growth in Vertical Industries

Country/Business: Italy/Digital Innovation

Main Objectives:

The purpose of 5GROWTH is to empower vertical sectors like Industry 4.0. Transportation and Energy with a collaborative and automated solution that helps them achieve their key performance targets with core 5G technologies. The project foresees a comprehensive multi-domain orchestration to create a portal that will interface with End-to-End platforms, plus a closed SLA loop to control the life cycles of vertical services. In addition, AI-driven solutions based on communication networks will jointly optimize access to resources across multiple domains. 5GROWTH will be field-tested in close collaboration with industrial partners like Comau, vendors and operators at four vertical sites (TRL 6-7), where network slicing architecture is required to guarantee higher security among communicating devices. It will also leverage on the results of 5G-PPP Phase 2 projects, where network function virtualization, remote support, telemetry and other solutions are being developed and tested. Once the pilot passes business validation, the consortium’s verticals will be offered the chance to influence ongoing 5G standardization with the involvement of experts in relevant SDOs.

- Partners

- COMAU (IT), UNIV. CARLOS III (E), NEC LABS (D), ERICSSON (E, I), INTERDIGITAL (D), NOKIA BELL (B) TELECOM (I), TELEFONICA (E), ALTICE (P), EFACEC (P), INNOVALIA (E), MIRANTIS (PL), NEXTWORKS (IT), TELCARIA (E), CTTC (E), IT (P), NKUA (GR), POLITO (IT), SSSA (IT).

HuManS – Human centered Manufacturing Systems and advanced human-robot interaction

Country/Business: Italy/Digital Innovation-Robotics

Main Objectives:

HuManS aims to create a new paradigm for high performance manufacturing systems. It leans on a human-centric approach, by doing research and development of advanced robotics such as collaborative robots, wearable exoskeletons and mobile robots to help workers interact safely and efficiently with automated machinery. The project also studies technologies like sensors for process monitoring and control based on Internet of Things (IoT) and intelligent components for adaptive workplace solutions. HuManS is part of the ERDF ROP 2014-2020 ‘Smart Factory’ technological platform, in which Comau had a leading role due to its expertise in industrial automation and robotics.

- Partners

- COMAU, FCA, FPT, CRF, HTC, ROBOX, LINUP, DMD, NOVASIS, POLIMODEL, PROLOGIC, MGM ROBOTICS, POLITO, UNITO, CNR-IEIIT

Project links: dmd

SiMonA – Sistemi di Monitoraggio Avanzato delle Linee di Produzione (Advanced Monitoring Systems on production lines)

Country/Business: Italy/Digital Innovation

Main Objectives:

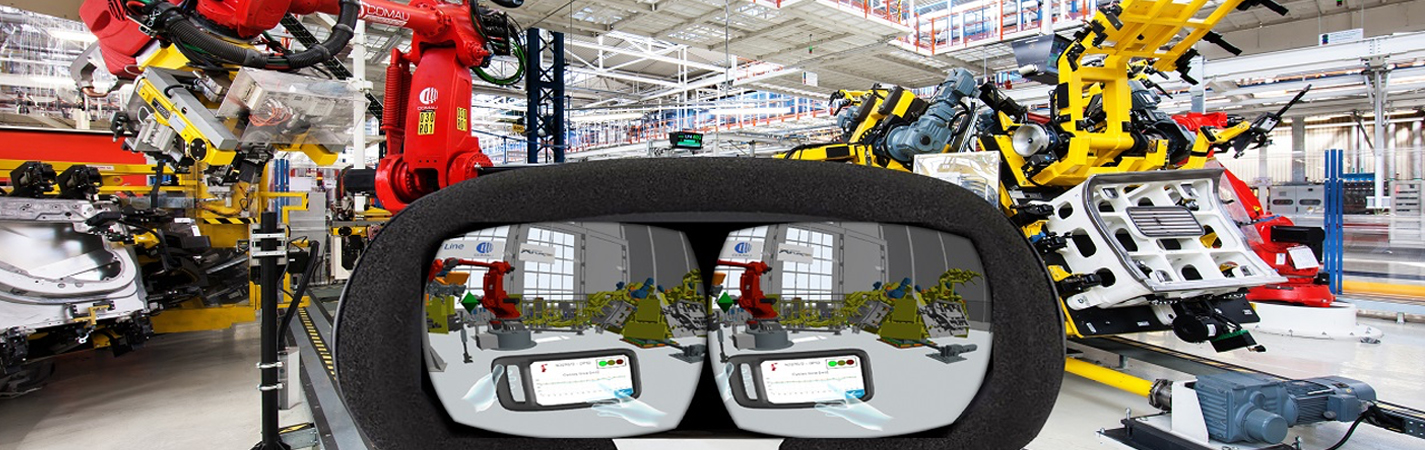

SiMonA has the objective of implementing advanced monitoring and control systems based on machine learning into highly complex production lines. The project seeks to demonstrate the efficiency of data analytics to manage predictive maintenance operations. The application of augmented reality tools can be used to promptly diagnose and service machinery, which in turn can minimize downtimes, improve the production process and even increase the energy efficiency of a factory by helping in the optimization of plant logistics.

- Partners

- COMAU, ENGINEERING

RAMEN – Resilient Industrial Platform for the Advanced Visualization of Predictive Maintenance

Country/Business: Italy/Digital Innovation

Main Objectives:

As a response to a real necessity that manufacturers face to stay competitive in a highly volatile market landscape, RAMEN offers a resilient Predictive Maintenance platform that supports companies in their operational strategies and maintenance tasks by gathering real-time data from their production facilities. Thanks to Industry 4.0 and IoT technologies, RAMEN provides intuitive analytics tools to help managers keep track of the state of machinery, thus reducing servicing costs. The platform assists shop floor personnel with AR/VR visualization and analytics technology that enables them to perform predictive maintenance activities in different use cases. This way, both SMEs and large companies can have a better outlook of production conditions and promptly intervene whenever needed, increasing efficiency and minimizing equipment waste. This solution was applied and validated at the premises of a manufacturer in the White Goods industry.

- Partners

- LMS - Laboratory for Manufacturing Systems and Automation, University of Patras, Biba, Whirlpool

Project links: Eitmanufacturing