In this interview, Gioacchino Civiletti, Product Manager at Comau, explains how he contributed to the Racer-5 SE: a “special”, high-performance and highly flexible robot, certified for use in the food industry and within sensitive environments, such as some e-mobility production processes. A robotic arm capable of supporting operators along the entire work line in a safe and agile way – from product handling to end-of-line operations such as packaging and de-palletizing, the result of a long study and experimentation project.

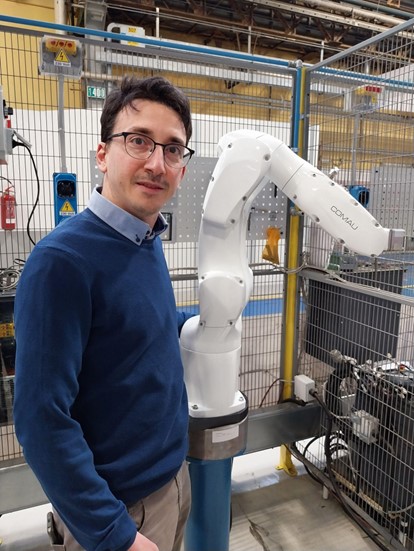

Gioacchino Civiletti, Product Manager di Comau

Gioacchino, what is your job at Comau?

I am an Electronics Engineer and have been with Comau for 10 years. I spent a long time in research and development for the robotics area, from a technical and engineering point of view, until, about 2 years ago, when I also wanted to test myself in the organisational area, to follow the complete development of a product, from the assessment of the relevant market to the relationship with potential customers. That’s how I managed the development of the Racer-5 SE robot for special environments, supporting Comau in a new application area, within the Product and Solution Management team of the Automated Advanced Solution division, as Product Manager. Currently, in this role, I am responsible for small and medium-sized robots, palletisers and arc welding solutions, especially for the food, beverage and pharmaceutical industries, where I am constantly looking for new uses and development opportunities.

What is the Racer 5-SE and what are its technical features?

The Racer-5 SE is our small 6-axis robot (with 5kg wrist payload) designed specifically for industries that are defined as “sensitive environments”, including food, beverage and pharmaceuticals. This robot is mainly used for product picking and moving applications, with and without packaging, where the hygiene levels of the working environment must always be at the highest level. The Racer-5 SE stands out from other robots for food grade lubrication (NSF H1) and coating resistance to major cleaning chemicals such as alcohol and hydrogen peroxide. The Racer-5 SE has also been designed to provide a high degree of dust and water protection (IP67) and to work in cleanrooms (up to ISO level 5). Finally, it is a product that is certified to work in contact with food.

How do you ensure that it is safe for use in the food industry?

Racer-5 SE has achieved MOCA (Materials and Objects in Contact with Food) certification, which is essential to be able to operate in direct and accidental contact with food. Two main aspects are assessed by this standard: the first is the suitability of the robot’s external surface for safe contact with food, demonstrated by tests carried out in an accredited laboratory; the second is the correct management of work processes, in line with GMP (Good Manufacturing Practice) in the food industry.

What are the benefits of the Racer-5 SE?

Racer-5 SE can be used to automate long, repetitive and unergonomic operations for the operator. A concrete case may be placing vials in a container for an entire shift, which often causes carpal tunnel syndrome for workers. A second example is the use of the robot inside cleanrooms: in these situations having the support of a Racer-5 SE avoids the continuous passage of personnel from an uncontrolled environment to a sensitive workroom, thus minimising the risks of contamination.

Can the Racer-5 SE also handle applications in the field of e-mobility?

Certainly. In addition to the aforementioned areas, this robot also has very promising applications in the field of e-mobility. For example, to manage battery cell assembly operations where, at some stages of the process, it is critical to avoid contacts that could compromise the quality and reliability of the battery cells.

Thinking about the development of this robot, what did you find most satisfying?

The construction of the Racer-5 SE was Comau’s first design experience in this type of application, so I am very proud to have contributed to its creation with teamwork lasting about 2 years. During this time, my colleagues and I have invested a lot of energy in studying and deepening the possible fields of application for this new robot and in offering the market advanced and competitive technology. We surrounded ourselves with high-level partners and all Comau divisions worked together, not only to achieve the desired technology solution, but also to certify it with MOCA and GMP, standards that can only be achieved through synergistic work at the company level. All the feedback we received from the companies we came into contact with and during the trade fair appointments confirmed the excellent work done and the quality of the product produced Acknowledgements that fill me with pride and are an important incentive to encourage our entire team to do better and better.

Contact Comau

You can get in touch with our Sales Area, by entering your contact information.