Comprehensive Hairpin Stator Technology Portfolio by Comau

Comau presents its hairpin stator technology portfolio, designed to cover the entire stator manufacturing process.

This solution underscores Comau’s commitment to innovation within e-Mobility, providing powerful turnkey solutions from design through execution. The portfolio reflects Comau’s strong engineering and electrification competencies, delivering a highly functional and fully validated solutions.

Comau’s Hairpin Stator Manufacturing Process

Explore the main features of hairpin stator processes, from prototyping to fully automatic production, and learn how Comau technology enhances efficiency, flexibility, and performance.

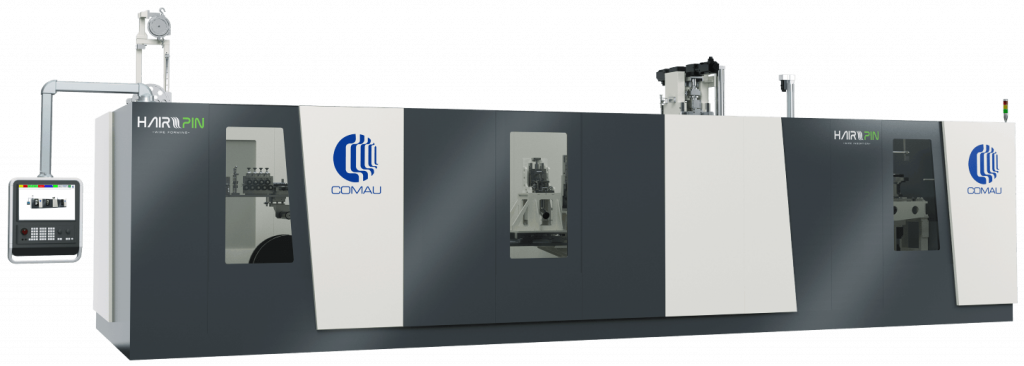

Wire Forming

- Fully automatic wire forming: unwinding → straightening → paint removal→ cutting → 2D NC forming → 3D mold forming

- High efficiency wire forming CT per pin<2s

- Wire straightness: <0.2mm

- High flexibility, high compatibility, high consistency of the pin forms

- High precision cutting function, cutting and chamfering are done at the same time in a single action without generating burrs

- Configurable laser/mechanical paint removal solution, ensuring high quality and cost-effectiveness

- Fully standardized functional module construction, compact design and small footprint

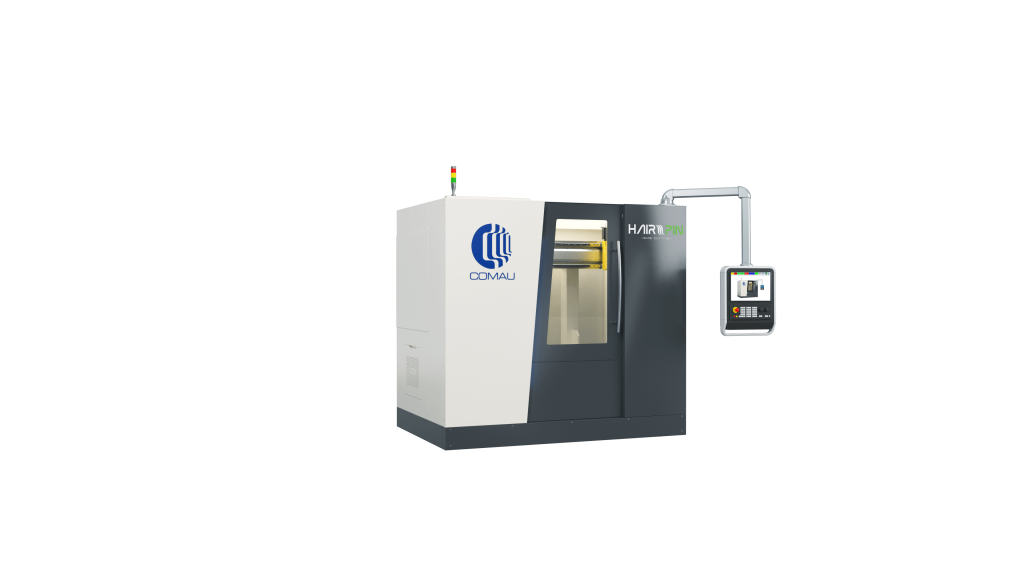

Wire Insertion

- High automation rate, no manual intervention required

- Highly compatible with wire types

- Ultra-high speed gantry movement with unwavering accuracy

- The corolla pressing is equipped with the insulating paper protection function

- Able to satisfy different special-shaped wire insertion requirements

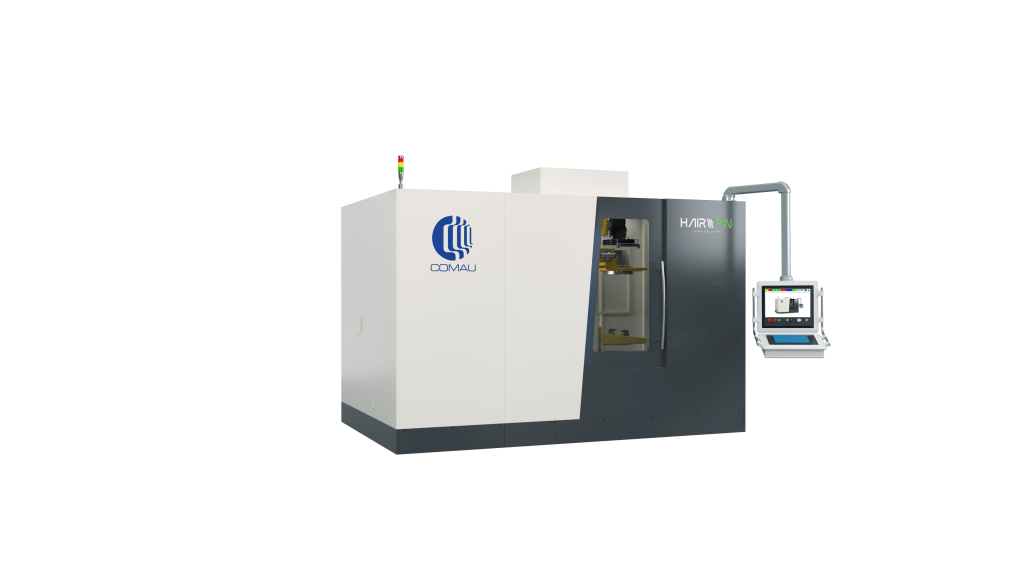

Wire Widening

- Optimized gripper to avoid damaging paint film

- Quick changeover of standardized modules

- Multi-configuration wire widening solution adapts to different stator types

- Multi-program precision control solves copper wire rebounding

- Level and smooth mechanism ensures that the paint film will not be damaged

- Wire widening tooling ensures in place wire separation using pass-through detection

Wire Twisting

- Twisting cylinder precisely controlled by the servo motor, smooth twisting process curve

- Ultra smooth twisting cylinder surface and wire / paper protection disk surface protect the wires from paint film damage

- Gear-driven twisting module with small footprint and high flexibility

- Separated twisting module and drive for quick changeover and optimized maintenance

- Multi-layer twisting mechanism synchronized rotation to ensure the accuracy

Wire Cutting

- The overall cam rotating structure uses a single, simultaneous cutting process to craft highly flat pin ends with no burrs

- Special material and ultra smooth wire clamping disk protects the wires from paint film damage

- Symmetrical design of the cutter increases the lifetime of the cutting tool and facilitates quick changes

- Special material and process adopted for the cutter, taking into account both the cutting force and lifetime of the cutter

Wire Welding

- Laser welding process ensures deep penetration, high pull-out force, high appearance grade

- Configurable welding process takes into account both quality and cost effectiveness

- Product option 1: Single machine for the cutting and welding processes ensures high welding quality with a compact footprint

- Product option 2: combined cutting and welding station for better line efficiency. Laser movable design, large coverage, and high flexibility

Benefits of Comau’s Stator Manufacturing Technology

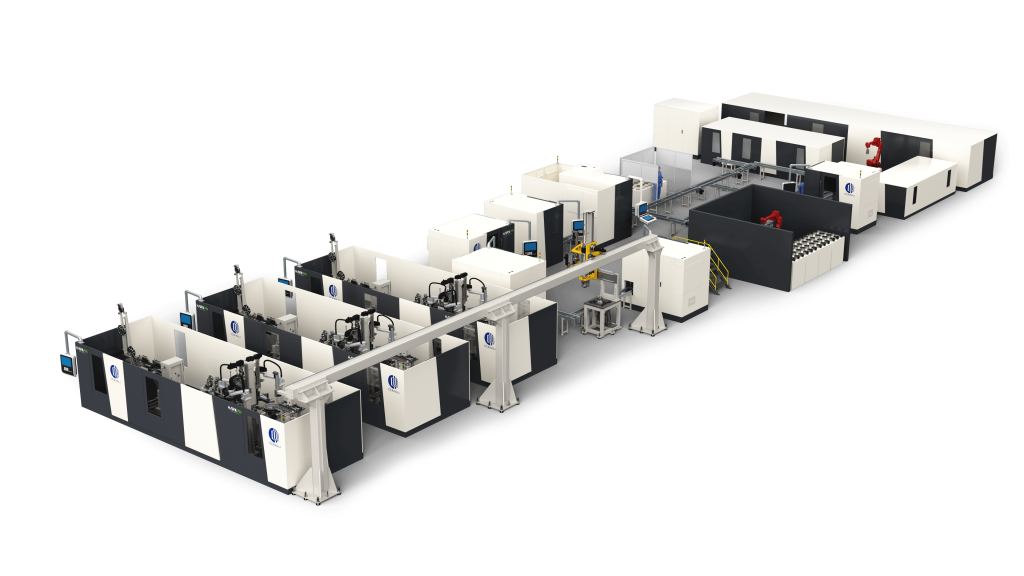

Efficiency and Flexibility: The fully configurable stator assembly line ensures efficient, flexible, and highly accurate end-to-end manufacturing of hairpin stators. The system can scale from a semi-manual to a fully automated process.

Versatility: Comau offers a one-stop solution for all e-manufacturing needs, simplifying the process for customers.

Optimized Footprint and Lean Production: The design minimizes space requirements and promotes lean production.

Real-Time Process Monitoring: Enhanced quality assurance through real-time monitoring of the manufacturing process.

Reduced Operational and Energy Costs: Optimized footprint and lean production set-up, real-time process monitoring for enhanced quality assurance, and reduced operational and energy costs.

One Partner For Entire E-Mobility Manufacturing System

Comau is leveraging its pioneering competencies in electrification and a 360° understanding of automotive manufacturing to help speed technology advances in the production of next generation E-Drive systems and batteries.

Engineering Excellence in Stator Manufacturing

Comau’s best-in-class stator process modules are developed at the Center of Excellence of E-Motor Technology in Shanghai. Key operation stations such as wire forming, insertion, widening, twisting, cutting, and welding are produced in-house by Comau China. This global presence with local roots allows Comau to quickly respond to worldwide market demands.

Global Solutions for Electric Vehicles and Motors

With leading R&D, prototyping, advanced manufacturing solutions and engineering expertise, Comau covers the complete E-Mobility manufacturing processes on a global scale. The launch of its proprietary hairpin assembly technology significantly improves production efficiency and flexibility. In addition to e-Motors, Comau’s expertise extends to battery assembly solutions, covering every stage from initial design and integration to optimization strategies and delivery of scalable turnkey production systems.

Our Offering

Comau offers a comprehensive suite of solutions tailored to meet the diverse needs of hairpin stator manufacturing. From customized prototyping services for Hairpin Stator A/B/C to scalable mass production lines, Comau ensures precision and efficiency at every stage of production.

Our versatile standalone machines, lean line planning, and multi-configuration lines provide flexible and optimized solutions, ranging from prototyping to fully automatic production.

With modular designs, integration of multiple processes, and advanced 3D layout simulations, we tailor our solutions to specific customer needs, supporting innovation and production efficiency.

Our In.Grid technology enables real-time monitoring and traceability, ensuring high-quality outcomes, while our customized equipment meets unique product requirements. Partner with Comau to leverage our expertise and drive your manufacturing processes forward with innovation and excellence.