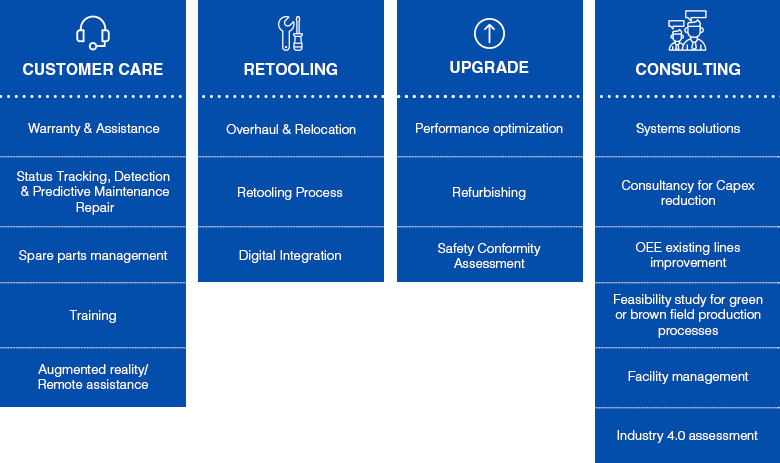

Wide-ranging support

Comau provides comprehensive cross-functional services starting with a worldwide customer care network, an extensive range of spare parts and customized training programs. We also deliver professional machine maintenance and analysis in addition to retrofit and retooling solutions. Our services cover any type of machine, regardless of the manufacturer, and include everything from set-up and commissioning to troubleshooting, testing and custom requests.

Customer care

Warranty & assistance

- Highly-qualified technicians

- Warranty checks to keep installed machines fully performing

- on demand Assistance and periodic assistance during production

- Site support as local presence

- Service for changes or modifications on installed machines

Detection & predictive maintenance, status tracking & repair

- Machine maintenance partnership concept to assist and complement our clients’ plant maintenance team

- Geometry check to detect deviations in any motion axis

- Fault detection and rectification via remote diagnostics (e-wan)

- Spindle performance remote monitoring, Dr. Spindle service

- Fast machine restart

Spare parts management

- Original spare and wear parts

- Package and Kit delivery

- Storage solution

Training

We provide standard and tailored training programs to get the most from our machines and maximize the return of your invested capital. Our training is developed based on your needs and is available for any industry and any product in our comprehensive portfolio.

- Standard & Advanced training

- Personalized Solutions

- e-Learning (multimedia learning)

- Augmented reality and Remote Assistance

- Comau web Academy

Our training courses cover all operational and maintenance tasks including mechanical, electrical, fluidic, programming and trouble-shooting, safety and ergonomics.

Retooling

Our worldwide retrofit is independent of manufacturer and machining processes and involves overhauling of machine tools and machine tool components including IoT solutions.

We complete the competence pattern with experts specialized in Purchasing, Manufacturing and Quality Management, Electrical Commissioning and Documentation.

Our expertise

- Process engineering & set-up

- Integration of new or reused machines

- Automation, logistics, grippers

- Refurbishing of old machines (any brand)

- Site management

- Digital Integration

Your needs

- Relocation & re-use of existing equipment

- Capacity extension

- New production program introduction

- Short shut-down period

- IoT implementation

Your benefits

- Trade off costs/quality

- Perfect solution between investment cycles

- On-time production restart & ramp-up

- Tailor-made approach: from different workpieces and project sizes up to turn-key systems

- Digital integration benefits

- Easy to use

- Easy to maintain

- Higher OEE (Overall Equipment Efficiency)

- Efficient support

- Better quality

- Continuous improvement

Digital retooling ensures on-going success

- Help for utilization & maintenance

- Preventive & predictive maintenance

- Digital twin services

- Remote assistance

- Spare parts management

- Safety of operators and machines

- Cyber security

Upgrade

Performance optimization

Thanks to our process know-how and longstanding experience, Comau service specialists can help increase the production output and efficiency of your machines and systems by modifying BT parameters, introducing new control systems or upgrading to new technologies.

- Preliminary technical discussion:

- Cycle time check of the current process

- Quality check of the current process

- Modifications to enhance cycle time and quality of output

- Improve reliability and maintainability of equipment

- Streamlined ROI

Refurbishment

Refurbishment can allow you to keep a traditional machine without scarifying reliability and quality as an ideal solution to bridge the period before making new technology investments

- Mechanical: repair of slides, replacement of wear parts, reconditioning of spindles, replacement of obsolete components, geometry adjustment.

- Fluidics: cleaning, leakage fixing, check and exchange of hoses, filters, replacement of obsolete components, adjustment of flow rate and pressure.

- Electric: refurbishing of electrical cabinets and panels, replacement of cables, sensors, actuators, replacement of obsolete components.

- Control Systems and Drives: replacement of obsolete equipment.

- Software: check and software upgrade.

Consulting

We are committed to helping companies improve their competitiveness. To do so, we deliver a powerful blend of competencies and real-world experience to identify and prioritize areas of improvements that can truly impact your business.

- Systems solutions

- Consultancy for CAPEX reduction

- OEE existing lines improvement

- Feasibility study for green or brown field production processes

- Facility management

- Industry 4.0 assessment