A comprehensive approach to system Integration

No matter how complex your machining needs, our results-oriented methodology and systems expertise can help get you up and running fast. We have the competence to develop any machining process and can assure productivity, flexibility and long-term quality with a wide range of modular products that span the entire production chain. In particular, we offer a complete range of assembly and test equipment within the machining process to deliver increased machining & assembly process consistency across the lifetime of your equipment.

Global Experience

Integrated Systems and Turn-key Solutions

Local Support

Modular Services Adapted to Your Business

Our expertise

- Process Engineering;

- Machining Modules, Ancillaries

- System Architecture

- Automation

- Workflow Logistics and Simulation of OEE (Overall Equipment Effectiveness)

Your needs

- Quality Achievement

- Reduced Life Cycle Cost

- Flexibility

Your benefits

- Easier Interface Management

- Guaranteed Process Quality

- High System Efficiency

Ancillaries equipment

We ensure productivity, long-term quality and continued reliability with a range of ancillaries including assembly and test equipment within the machining process. We also perform activities ranging from marking and final inspection to handling/logistics and integrate outsourced operations to offer complete turn-key systems including honing, washing and measuring. In other words, we deliver integrated solutions that fully accommodate your diverse manufacturing needs – today and tomorrow.

Why

- To manage the whole process through one unique supplier

- To reduce project management costs (single commissioning site, logistics of trial parts)

- To improve machining & assembly process consistency

What

- A complete range of assembly and tests solutions

- Robotics solutions for high flexibility

- Suitable for any kind of process, from manual to automatic

Value Proposition

- One supplier for both machining and assembly process

- Reduced logistics of trial parts

- Process quality

- High level of flexibility and re-usability

List of ancillaries made by Comau

- Guide & Seat Assembly Station

- Leak test (intermediate and final)

- Steel balls / plugs / Dowels Assembly station

- Caps / bedplate / Ladder frame assembly

- Marking station

- Final inspection

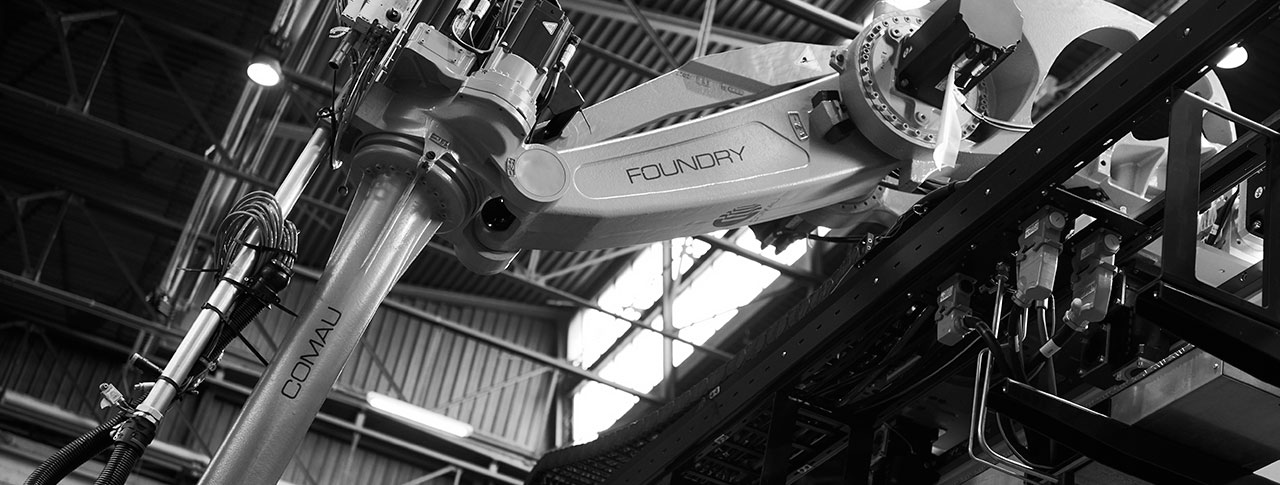

Automation

Why

- To manage the entire process through one unique supplier

- To facilitate interfaces

- To suit to your production level requirement

- The logistics of production line is the backbone of the system

What

- A range of solutions for your production line

- Robot supply and integration

- Engineering and supply of specific gripper and floor automation

- Virtual commissioning

Value Proposition

- One turnkey supplier mastering the logistics and the interfaces

- Enhanced OEE

- High level of flexibility and re-usability

- Anticipated new or retooling validation by virtual commissioning