A NEW PARADIGM IN SUSTAINABLE AUTOMATED ON-SITE SOLAR BLADE INSTALLATION

• Comau’s patented mobile factory grants better safety and sustainability by automatically installing solar trackers directly in the photovoltaic field

• With an installation rate of up to 30% more modules per hour per operator compared to standard processes, Hyperflex facilitates faster plant construction and subsequent renewable energy production

• Up to 25% faster time-to-market for new plants with an average price per panel savings of 35%

• The flexible design can accommodate different types of trackers and panels, allowing it to easily adapt to the specific needs of different energy providers

Grugliasco (Turin), June 27, 2023

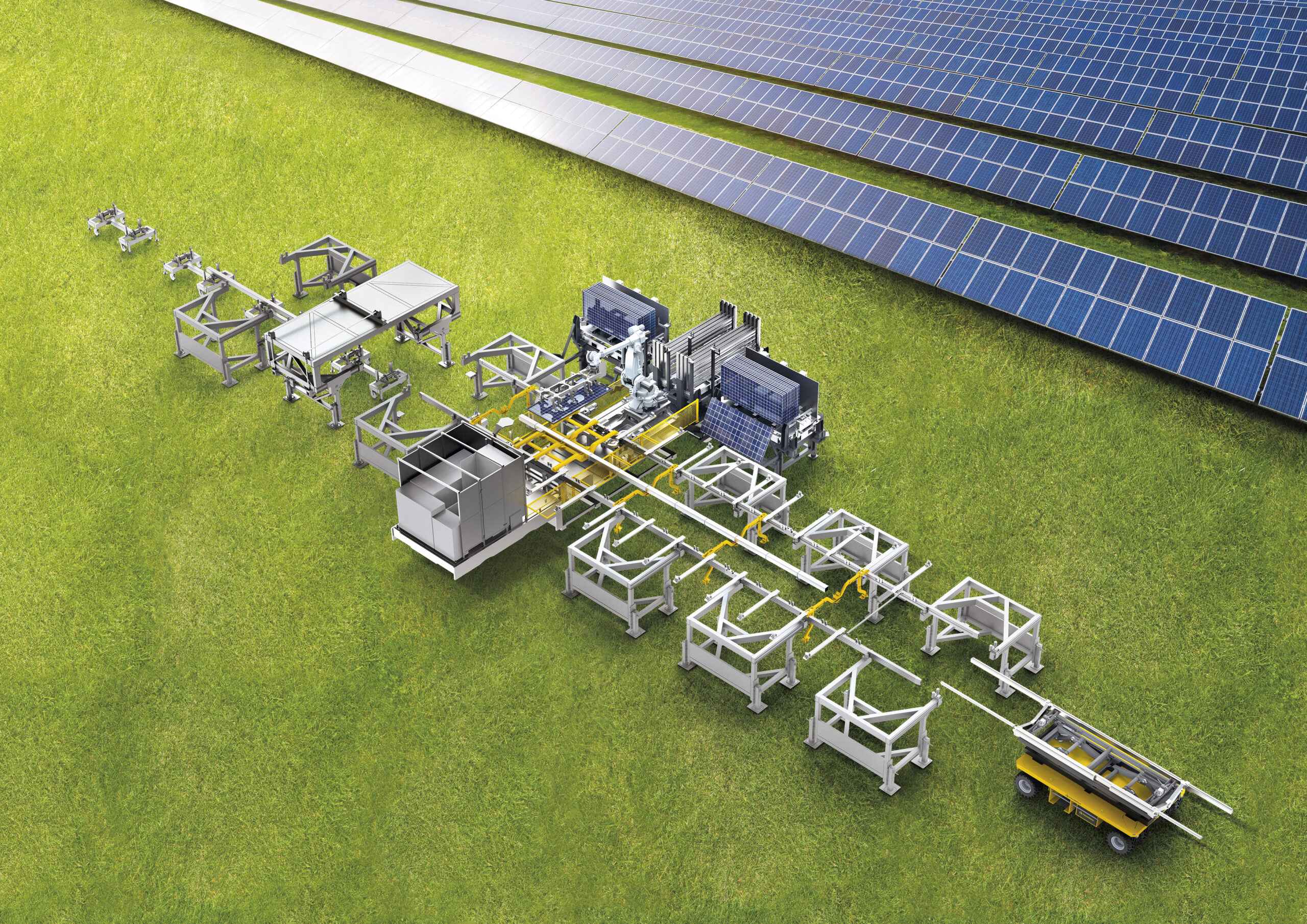

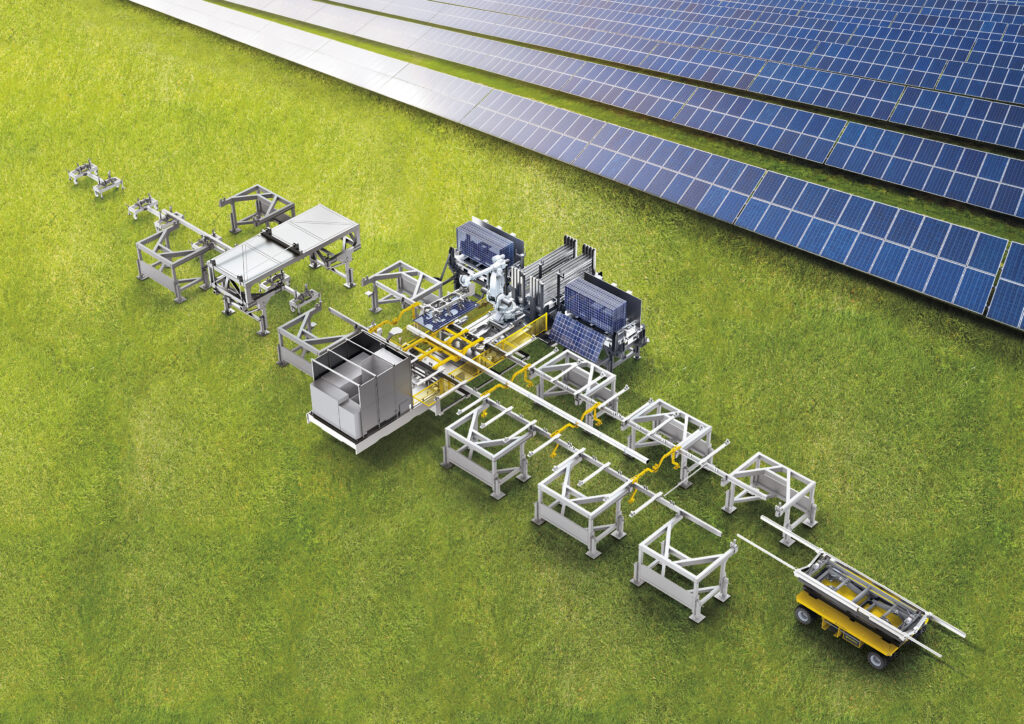

Comau debuts its patented Hyperflex mobile factory, a new paradigm in solar blade deployment that facilitates faster photovoltaic plant construction for a time to market savings of up to 25% on new installations. Designed in-house and featuring proprietary Comau robotics, lifting equipment and other technology enablers, Hyperflex automatically assembles the entire solar blade, which can measure up to 48m2, directly in the photovoltaic field. In doing so, the robotized temporary mobile factory lowers overall operating costs while granting better operator well-being, process quality and overall productivity when expanding an existing plant or installing a new one. Furthermore, Hyperflex’s flexible design can accommodate different types of trackers and panels, allowing it to easily adapt to the specific needs of different energy providers.

With Hyperflex, Comau has collapsed the traditional manufacturing and installation process into a highly efficient, on-site procedure that manufactures the torque tube, transversal beam and PV module in a single, robotized production station. Through an optimized mix of manual and automated processes, in which human operators work alongside the robot in complete safety thanks to advanced laser scanning techniques, HyperFlex supports green energy production while improving the working conditions of the operators. With an installation rate of up to 30% more modules per hour per operator compared to standard processes, Hyperflex also facilitates faster time-to-market for new plants of up to 25% with an average price per panel savings of 35%. The robotic solution can therefore play a decisive role in helping achieve Europe’s renewable penetration goals.

As a temporary mobile factory, the entire solution is housed inside a semi-trailer that can be easily shipped from one solar plant to another. In addition to granting centralized control of the entire process and creating a new, KM 0 logistics flow directly in the field, Hyperflex improves efficiency while reducing overall energy consumption. It also improves the photovoltaic value chain at a plant level and allows in-field operators to play a fundamental role in quality control and process management. Furthermore, Comau’s industrialization of the solution will help the journey of energy conversion. And because the flexible design easily accommodates different types of trackers and panels, it can be tailored to meet the specific needs of different energy providers.

Better quality and lower overall costs in solar blade installation

“Reducing costs for solar farm installation is of paramount importance and a key factor in meeting the world’s net zero emission targets. Based on internal estimates and supporting market research, we believe global photovoltaic panel installation for solar farms will experience a 10% CAGR between 2022 and 2030. Hyperflex is well-positioned to speed the deployment of new installations while ensuring better quality, increased efficiency, and lower overall costs, helping our customers contribute to making sustainable solar energy a reality.”

Nicole Clement, Chief of Advanced Automation Solutions at Comau

Downloads

About Comau

Comau, a Stellantis company, is a worldwide leader in delivering sustainable advanced automation solutions. With 50 years of experience and a global presence, Comau is helping companies of all sizes in almost any industry leverage the benefits of automation.

Backed by a continuous commitment to designing and developing innovative and easy to use technologies, its portfolio includes products and systems for vehicle manufacturing, with a strong presence in e-Mobility, as well as advanced robotics and digital solutions to address rapidly growing markets in industrial sectors.

The company’s offering also extends to project management and consultancy. Through the training activities organized by its Academy, Comau is committed to advancing the technical and

managerial knowledge necessary to face the challenges related to automation and

leverage the opportunities of a constantly changing marketplace.

Headquartered in Turin, Italy, Comau has an international network of 5 innovation centers, 5 digital hubs, and 12 manufacturing plants that span 13 countries and employ 3,700 people. Together with its wide network of distributors and partners, the company is able to respond quickly to the needs of its customers, no matter where they are located throughout the world.

Contact Comau

You can get in touch with our Press Office and Media area,

by entering your contact information.