Electrification

From mobility to industrial manufacturing, Electrification is reshaping European industry. Comau provided its expertise on the matter to different EU projects aimed at supporting key industries and local SMEs with such a relevant transition. Electrification is an important requirement to guarantee a greener, more sustainable production model.

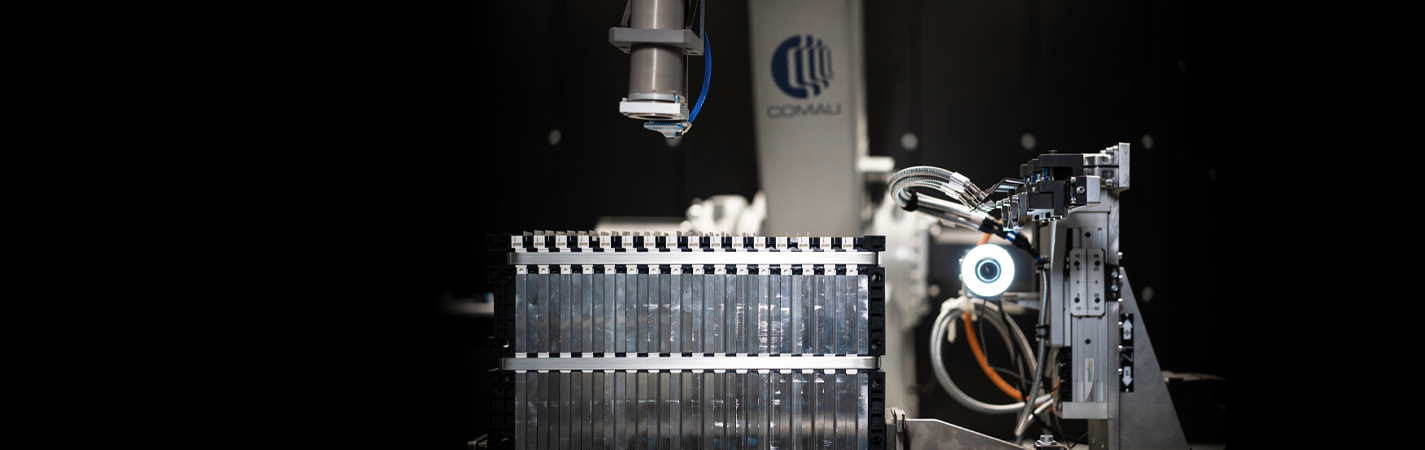

ZELD-e: Zero-defect welding for e-mobility

Country/Business: Worldwide/Electrification-Automation Systems

Main Objectives:

Battery packs are composed of multiple individual battery cells that are structurally held and electrically connected by numerous welded joints. This means that high electrical resistance, due to poor joint quality, can create high energy loss and heat generation, thus increasing the joint temperature, provoking potential safety issues, and reducing efficiency. Given the significant number of welded joints in electric battery packs, the fast and efficient assessment of each single joint is fundamental to reducing costs and increasing battery safety.

The ZELD-e project aims to introduce a complete solution to monitor and control the laser welding processes for EV batteries. It consists of an inline, non-invasive testing and quality control system based on an infrared sensing setup that is enabled by artificial intelligence and computer vision algorithms. The camera is installed directly on the laser head, ensuring the ability to adapt to different battery configurations and typologies. The solution, which targets both tab-to-tab and tab-to-busbar laser welding applications, guarantees battery integrity and prevents waste, thus maximising the efficiency of the production line without impacting the cycle time or manufacturing layout.

- Partners

- LMS - Laboratory for Manufacturing Systems and Automation, University of Patras, Irida Labs, I-FEVS, CASP

Project links: Eitmanufacturing Zeld-e

PURE

Country/Business: Worldwide/Electrification-Automation Systems

Main Objectives:

PURE project intends to transform a good innovation (widely qualified and validated) into a great industrialized product.

The APA (technology by ISCLEANAIR) solutions are based on a very easy and effective process to purify the air from contamination, pollution and even harmful micro-organisms as viruses: unique water-based and mechanical processes remove the pollutants present in the ambient air and, with air cleaning (washing) cycles, obtain the dilution principle and the elimination of harmful elements in simple water, down to the smallest, nastier sizes and types including gases, VOCs, NOx, SOx, heavy metals and hydrocarbons, but also superfine nano-particulate matter, viruses, bacteria and mould spores.

PURE Project introduction

Air Pollution Abatement System by ISCLEANAIR

- Partners

- COMAU, Is CLEAN AIR, CEA, FAGOR

Project links: PURE

VERIFy – Visually GuidEd Robotised Cell for Finishing Processes

Country/Business: Italy/Electrification-Automation Systems

Main Objectives:

The main focus of VERIFy is to develop an automated detection System for quality control and corrective tasks in manufacturing processes that require casting. It features an autonomous robotic cell that inspects casted parts and detects their possible aesthetic defects thanks to its innovative Vision System. Afterwards, the VERIFy system can classify the defective part as scrap or as to-be-finished, where a force feedback-enabled robot handles the finishing process on the spots where said defects have been identified. Automating a process that is traditionally done manually leads to a more accurate diagnosis and minimizes equipment deburring. The project seeks to increase production efficiency and reduce ergonomic strain on human workers.

- Partners

- COMAU, Brembo, LMS - Laboratory for Manufacturing Systems and Automation, University of Patras, CASP, POLIMI

Project links: Eitmanufacturing

RoboFIETS – Sustainable human-robot co-production for cargo bicycles

Country/Business: Italy/Electrification-Robotics

Main Objectives:

The RoboFIETS project studies the potential of assistive technologies and human-robot co-production in order to create added value for the European E-bike industry. The research team analyzed the feasibility of automation in 16 assembly lines and developed three prototypes to optimize the manufacturing of personalized bicycles, which in contrast to mass-production follows different standards and requirements. With tools like VR and exoskeleton aids, RoboFIETS can make workplaces more sustainable and inclusive for all workers.

- Partners

- COMAU, Accell Group, Tu DELFT, Chalmers University of Technology

Project links: Eitmanufacturing