Grugliasco (Turin), Nov 6, 2024

Comau is bringing the Power of Automation to EXPO INDUSTRIA 2024 Vicenza (Vicenza Fiere, Hall 1, Booth 43) from November 6th to 9th, 2024. The event, now in its third edition, is a perfect occasion to share the innovation and technological improvements that will help companies in the Vicenza Industrial District stay competitive in an increasingly global and ambitious market. In addition to traditional welding techniques, manual and automatic laser welding solutions will also be shown at the conference, as well as additive manufacturing, collaborative robots and traditional robots for welding applications.

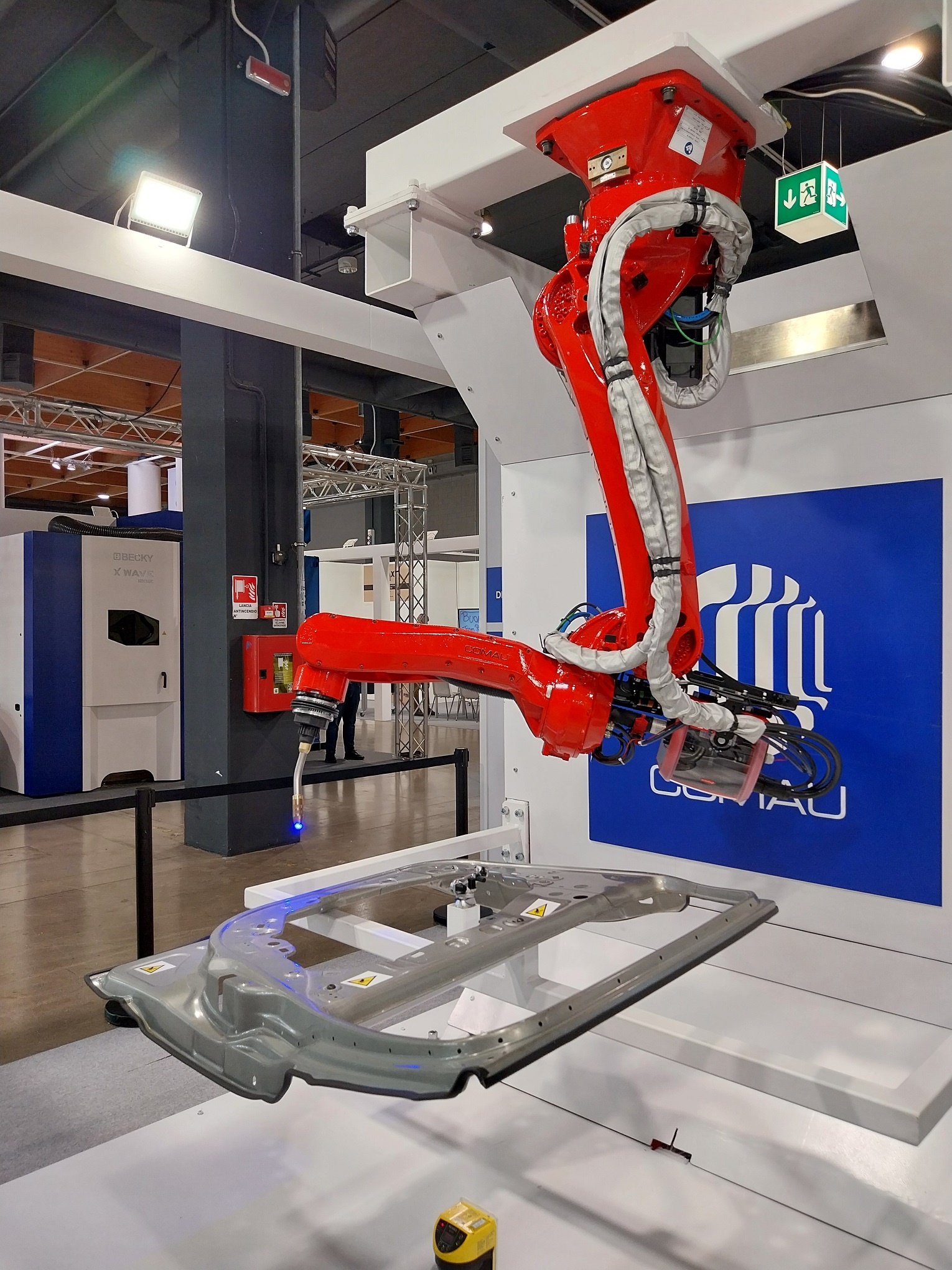

To boost innovation and growth of the district, which is well-known for having a large concentration of arc welding applications in various production and assembly processes, Comau will put its experience and expertise on display together with some of its latest technologies – from the S-family robots to the new TPX Robot Teach Pendant – designed to automate key welding and arc welding operations.

At the Comau booth, visitors can see two key demos that underscore the technological excellence of Comau’s solutions for arc welding. The first is a fully automated Arc Welding cell integrating two S-Family robots, the S-18 and the Compact models. The second cell features the 6-axis educational robot e.DO working together with Seabery Soldamatic as part of a simulated robotic welding application that offers a realistic hands-on learning experience. The integrated and customizable simulated training program, based on augmented reality, allows users to program a robot in PDL2 using the SmartArc APP to simulate welding processes. They can also access structured pathways and practice exercises with real-time monitoring and detailed feedback, to improve their welding techniques.

Comau is also presenting its new TPX Robot Teach Pendant, which introduces new ways for users to operate, program, and monitor robots. Thanks to its large touchscreen display and an advanced Human-Machine Interface (HMI) that features intelligent programming paradigms and 360° control functionalities, the TPX Teach Pendant simplifies the management of one or more robots. Furthermore, the integrated 3D simulation features allow users to visualize and modify robot tracks in real-time, reducing setup times and improving the overall system efficiency.

On November 7, at 3:30 PM, Gioacchino Civiletti, Product Manager at Comau, jumps on stage to speak about the “Benefits of the Hollow Wrist and Integrated Solutions for Automated Arc Welding Applications”. He also addresses the emerging role of the S-Family robots in designing and developing ARC Welding applications.

“The S-Family represents a new generation of robots combining technological excellence with Comau’s expertise to support the emerging needs in welding applications. The two S-Family robot models bring flexibility and excellent performance in terms of cycle time, repeatability, and path control accuracy. They improve welding techniques, helping to save time and materials.”

Gioacchino Civiletti, Product Manager at Comau

Confirming its role as a strategic partner in the arc welding segment, Comau is leveraging EXPO INDUSTRIA 2024 Vicenza, to help companies in the Veneto region improve the quality of their welding operations and manufacturing processes. In tandem, Comau’s solutions help reduce cycle times and costs, thanks to safe, sustainable and repeatable processes. Comau’s advanced and scalable automation thus becomes essential in automating arc welding operations, and ensuregì maximum safety and quality levels.

Comau is looking forward to welcoming visitors and partners at EXPO INDUSTRIA 2024 Vicenza to showcase excellence in automation for welding operations. To register for Expo Industria at the Fiera di Vicenza, click HERE.