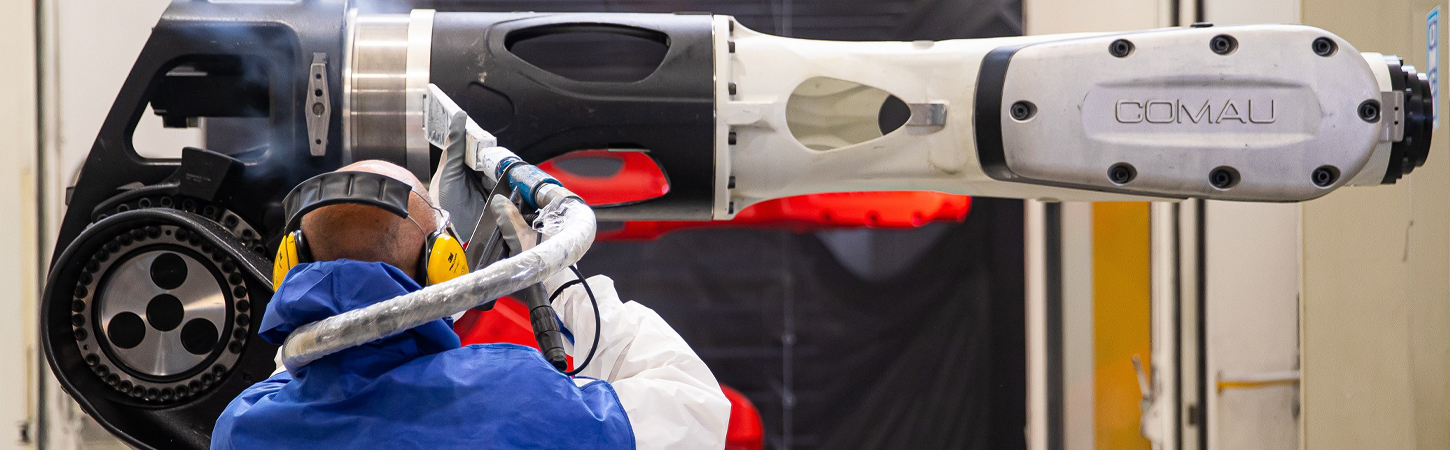

With the goal of managing industrial processes with maximum efficiency and in line with sustainability goals, Comau began experimenting with cryogenics for cleaning robots and spare parts before painting. The pilot project was carried out in collaboration with Camic, a supplier specializing in industrial painting, and Cryos, leader in dry ice blasting.

From studies conducted internally, Comau has found that there are multiple benefits to using this new technology.

The use of dry ice, instead of traditional water washing, not only preserves the performance of robots over time, but also cleans every facility extremely thoroughly, saving water, reducing energy consumption and eliminating the release of harmful substances into the environment.

Cryogenic blasting uses CO2, a by-product generated by many manufacturing plants, or from natural sources, captured before being released into the atmosphere, liquefied and frozen in the form of pellets of varying sizes. It does not require the use of water or chemical agents, such as degreasers and leaves no residue on the treated surface at the end of the cycle. In addition, drying the treated parts and subsequent water treatment in the traditional process is no longer necessary. The cryogenic process also reduces part cleaning and project completion times. Dry ice is non-abrasive, so it doesn’t damage the treated parts, it improves the adhesion and resistance of the paint on the robot’s surface over a long period of time. Not electronically driven, it allows the cleaning of electrically energized, equipment, eliminating the risk of plant downtime and associated impacts on production. Based on these characteristics, the process therefore ensures safety and is useful for protecting the health of operators.

“By adopting this new process, Comau wants to increase customer satisfaction and offer increasingly efficient, durable and sustainable products. Indeed, quality and sustainability are fundamental foundations of all Comau activities. The adoption of this technology is part of a sustainability journey that Comau is continually pursuing and integrated within its divisions to achieve increasingly concrete and effective ESG (Environmental, Social, Governance) practices.”.

Salvatore Lorusso, Quality Manager for Engineering and Sustainability Ambassador