COMAU UNVEILS END-TO-END HAIRPIN STATOR SOLUTIONS FOR E-MOTOR MANUFACTURING

• Comau’s new hairpin stator manufacturing solution ensures efficient, flexible and highly accurate end-to-end production of hairpin stators, an integral part of electric motors

• Backed by 50 years of process expertise and strong electrification competences in automotive manufacturing, the brand-new proprietary technology is scalable and designed to meet current and future production needs

• The comprehensive portfolio, which covers the entire electric motor value chain, reconfirms Comau’s position as a turnkey OEM & Tier1 e-manufacturing partner

Share this article

Shanghai – July 17, 2024

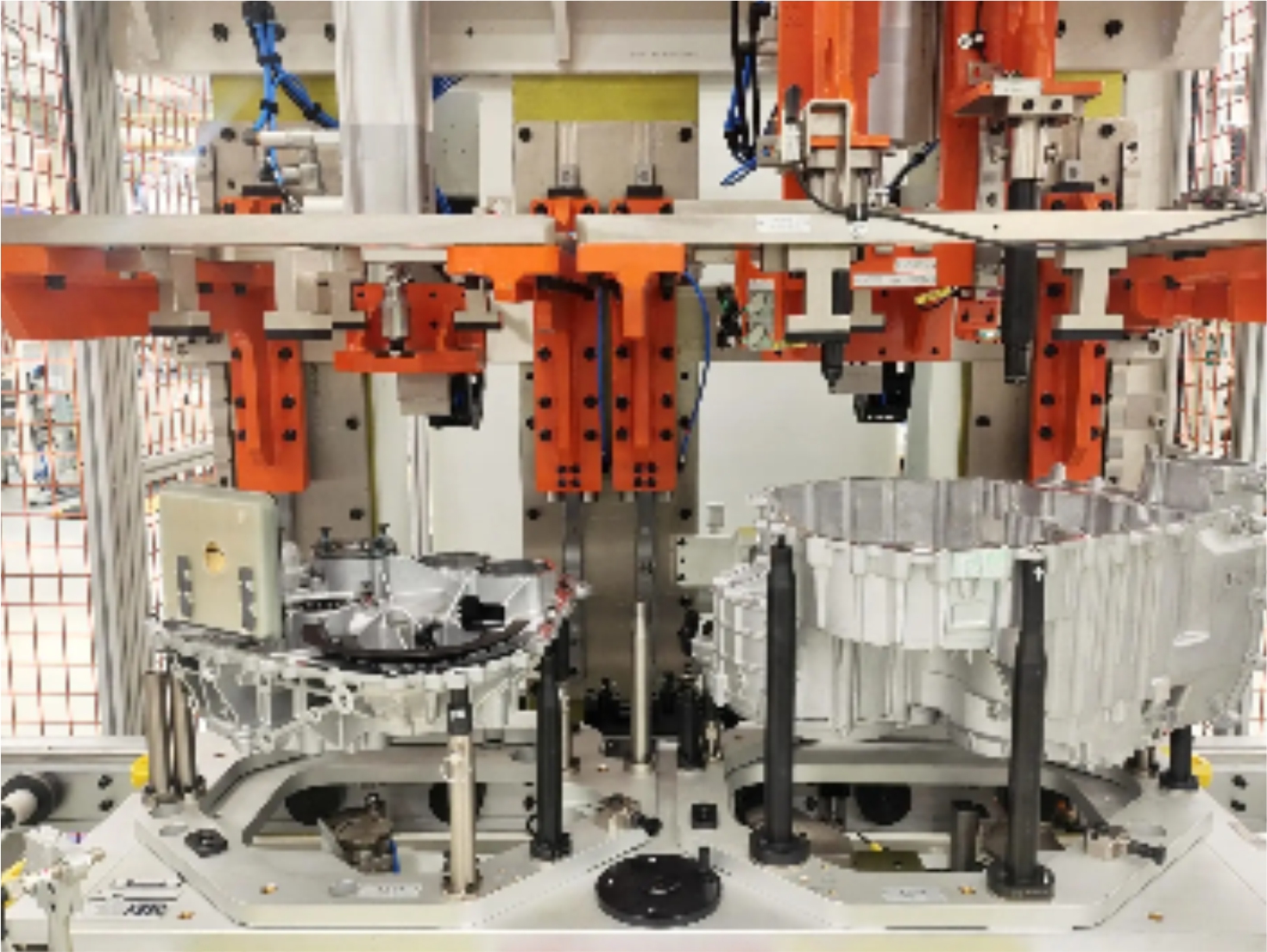

Comau has launched a comprehensive hairpin stator technology portfolio covering the entire stator manufacturing process, from hairpin wire forming, insertion to wire widening, twisting, and from laser welding all the way to quality testing and control checks.

Underscoring Comau’s commitment to innovation within e-Mobility, the expanded offer reinforces the company’s ability to provide powerful turnkey solutions for the entire motor assembly process from design through to execution. It also reflects Comau’s strong engineering and electrification competencies, having delivered a highly functional and fully validated solution within years of having developed the initial prototype line.

As a critical structural and functional element within an electric motor, stator production is a complex process that necessitates high precision and control levels. Comau’s fully configurable stator assembly line ensures efficient, flexible and highly accurate end-to-end manufacturing of hairpin stators with the inherent scalability to move from a semi manual to fully automated process. This level of versatility offers customers multiple benefits including the opportunity to work with one partner for all their e-manufacturing needs.

In addition, Comau’s engineering approach is designed to meet current and future production scenarios and can acutely address customers’ pain points. Other benefits include the optimized footprint and lean production set-up, real-time process monitoring for enhanced quality assurance, and reduced operational and energy costs.

Comau’s best-in-class stator assembly modules were engineered within the company’s Center of Excellence of E-Motor Technology in Shanghai with the key operation stations as wire forming, insertion, widening, twisting, cutting and welding produced in-house by Comau China. This achievement represents Comau’s strategy of having a global presence with local roots, as it both complements China’s growing e-drive trend and allows Comau to quickly respond to worldwide market requests with global organization.

With its leading R&D, prototyping, mass production and engineering expertise, Comau can provide tailored solutions to electric vehicle and motor manufacturers on a global scale. This includes batteries in addition to e-Motors and e-vehicle assembly solutions. The launch of its proprietary hairpin assembly technology is designed to help customers significantly improve the efficiency and flexibility of their production environment. In the battery domain, on the other hand, Comau’s competence spans every stage of the assembly process, from the initial design and integration to optimization strategies and the delivery of flexible and scalable turnkey production systems.

The growing demand for hairpin stators

“The newest solution within our robust e-Mobility offer meets the growing demand for hairpin stators by automakers around the world. It also complements our ability to design and implement value-driven electrification solutions that increase manufacturing efficiencies while ensuring the high level of quality and excellence Comau is known for” emphasized Pietro Gorlier, Comau CEO. “We believe there is significant market potential for our turnkey hairpin assembly lines to support the estimated global growth of the e-Motor market, which is expected to continue its double-digit growth rate*. As the e-Mobility scenario continues to evolve, Comau’s broad ranging competence and versatile skills set allow us to respond to the specific needs of our different customers.”

*according to internal estimates and supporting market research.

Pietro Gorlier, Comau CEO

“Comau is very proficient in the assembly of E-Drive systems and was one of the first companies to heavily invest in this technology several years ago. Furthermore, our APAC R&D center, the China innovation center and Shanghai plant, continue to support global R&D and production. Comau Hairpin Stator Solutions, which were self-developed in China and launched worldwide, will significantly advance global automotive manufacturing towards greater efficiency and greener intelligent technologies.”

Jeff Yuan, Comau APAC Countries Cluster Lead

Downloads

About Comau

Comau, a member of Stellantis, is a worldwide leader in delivering advanced industrial automation products and systems. Its portfolio includes technology and systems for electric, hybrid and traditional vehicle manufacturing, industrial robots, collaborative and wearable robotics, autonomous logistics, dedicated machining centers and interconnected digital services and products able to transmit, elaborate and analyze machine and process data.

With 50 years of experience and a strong presence within every major industrial country, Comau is helping manufacturers of all sizes in almost any industry experience higher quality, increased productivity, faster time-to-market and lower overall costs. The company’s offering also extends to project management and consultancy, as well as maintenance and training for a wide range of industrial segments.

Headquartered in Turin, Italy, Comau has an international network of 7 innovation centers, 12 manufacturing plants that span 12 countries and employ 3,700 people. A global network of distributors and partners allows the company to respond quickly to the needs of customers, no matter where they are located throughout the world.

Through the training activities organized by its Academy, Comau is also committed to developing the technical and managerial knowledge necessary for companies to face the challenges and opportunities of Industry 4.0.

Contact Comau

You can get in touch with our Press Office and Media area,

by entering your contact information.