Shanghai, Apr 12, 2024 – The 10th Automotive Advanced Technology Manufacturing Summit was held April 10-12 in Chongqing, China. With the shared objective of advancing China’s automotive manufacturing technology forward, the summit brought together numerous renowned domestic and international OEMs, alongside over 1,800 automotive experts, to exchange ideas in the fields of welding, final assembly, digital factory technologies, gigacasting, and to discuss new trends, technologies, processes and application scenarios in the automotive industry.

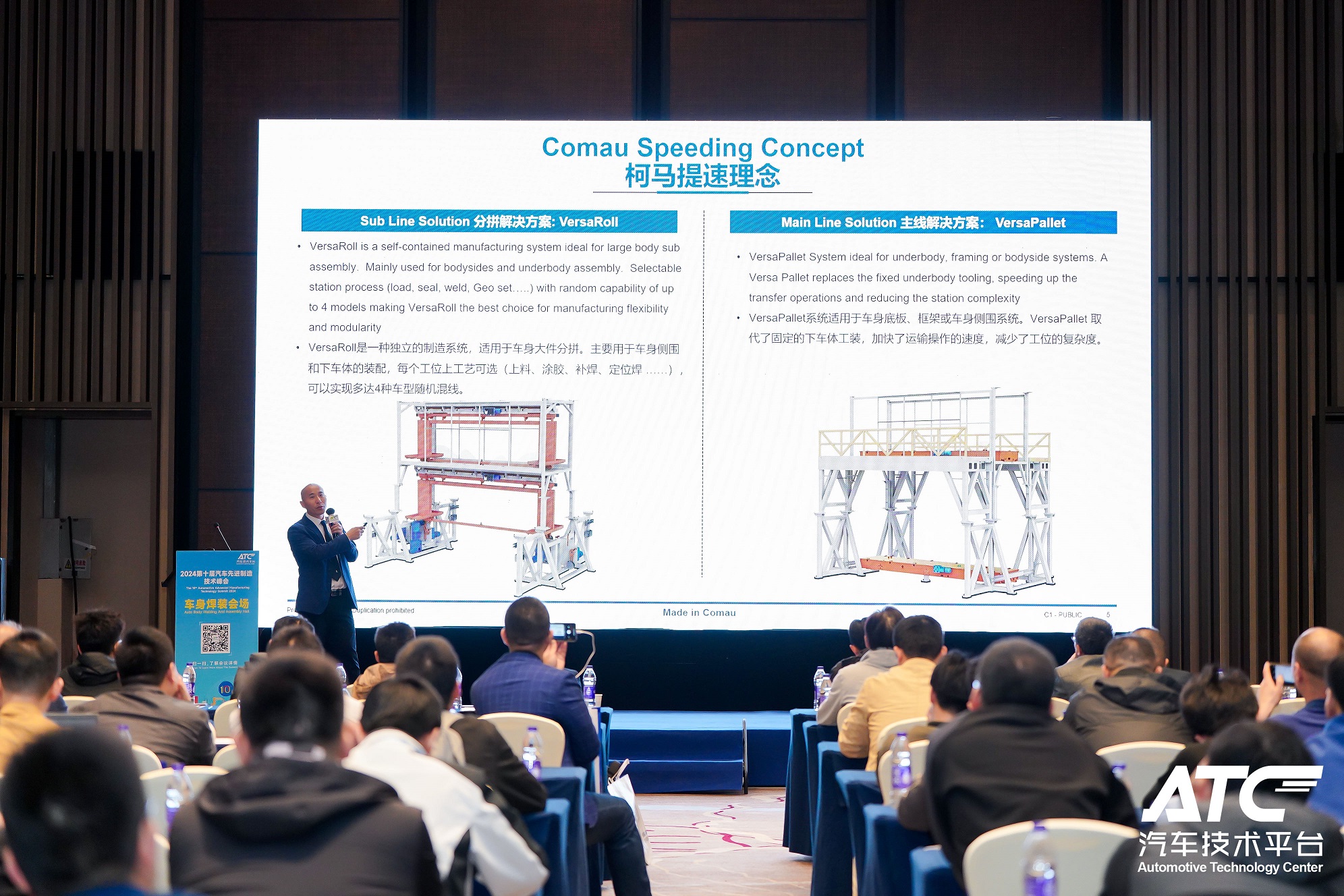

As part of the event, Jeff Yuan, Comau APAC Countries Cluster Leader, gave a keynote speech at the main event forum. During his address, he presented Comau’s manufacturing solutions for the automotive industry, focusing on production systems, batteries and electric drives, all geared towards improving quality and efficiency for customers.

Meeting the needs of different users is a key factor in implementing digitization projects and achieving the expected returns. Comau’s digital solutions focus on equipment status and monitoring of the entire production process. For example, the in.Grid platform enables the interconnection of production equipment based on automation, leanness and flexibility, ensuring that performance and process information is calculated as accurately as possible and that the production process is transparent and paperless, deeply optimizing production efficiency for factories.

During the concurrent body welding assembly forum, Mark Xu, Comau China Body Assembly Proposal Manager, emphasized the benefits of the new generation of the High Speed PowerRoll Bed. As a commonly used transmission system in the welding shop, the utilization of the pallet is essential for enhancing the flexibility of the production line.

The upgraded hardware and optimized motion control of the new generation of the High Speed PowerRoll Bed not only ensure high positioning accuracy but also increase the transfer speed by 25%. With a remarkable track record of over two years of trouble-free operation in two projects, this product has proven to be highly stable and reliable. Equipped with on-site distributed motion control devices, the High Speed PowerRoll Bed is easy to maintain and provides robust support for improving production efficiency.

In addition, Comau presented the technical advantages and application scenarios of the company’s latest solutions and products, generating great interest among attendees. Leveraging over 50 years of automotive expertise, rich manufacturing experience and advanced R&D, Comau is committed to the continuous expansion of the comprehensive value chain, including NEV (New Energy vehicles) as well as conventional vehicles, through a diverse technological spectrum, the company addresses market challenges and provides customers with tailored solutions and services to meet their production needs.