Comau’s participation in Battery Innovation Days was a big success. The important industry conference was well-attended by customers, suppliers, institutions and government agencies episode of our interview series features Daniela Fontana, who will tell us more about Comau’s funded projects and the pioneering technologies that is making Comau the partner of choice for some of the world’s biggest Electrification companies.

Please introduce yourself and tell us about your role in Comau

Hi, I’m Daniela Fontana and I am responsible for Comau’s Funded Projects Management within the E-Mobility Global Competence Center.

Tell us about what you presented at Battery Days

In addition presenting Comau’s competencies in battery manufacturing and making new contacts, I took part in an important industry roundtable, Towards more sustainable battery: challenges and innovation which was held within the panel Sustainable Batteries as an integral step in reducing products’ carbon footprints. Here, I was able to speak about sustainability in battery production from a plant perspective, which includes reducing energy consumption in plants, and was able to present the results of Comau’s Flex-BD (Flexible Battery Dismantling) project.

What do you hope to have achieved during the event?

The event was an important venue to meet industry professionals as well as potential customers who were excited to learn more about Comau’s solutions portfolio in regard to the battery field. In addition, as one of the panelists during the roundtable, I had the opportunity of sharing with experts of the sector needs and inputs for a sustainable battery value chain in Europe.

Why is Comau’s participation in funded projects and industry consortiums important?

Our participation within industry groups and international research projects also enables us to accelerate our development effort and exchange ideas/best practices with institutions, organizations and service providers along the e-Mobility value chain.

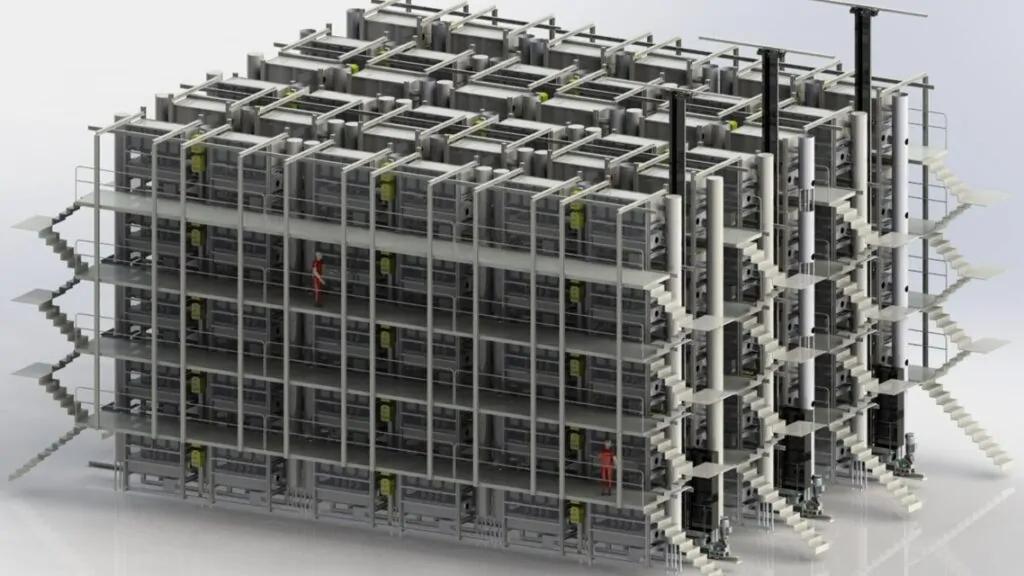

Looking at SPINMATE, for example, we are developing a proof-of-concept pilot line as a first step towards the large-scale manufacturing of generation 4b solid-state battery cells and modules. With GIGABAT, a collaborative e-Mobility project aimed at strengthening the EU production chain for large-scale cell manufacturing, we are designing an innovative cell chamber that recovers and reuses excess heat and electricity produced during the intense, multi-day cell activation procedure.

By developing advanced solutions for cell formation, next-generation battery manufacturing and end-of-life battery management, we are increasingly able to provide a 360° cradle-to-grave e-Mobility strategy.

Discover how Comau is boosting E-Mobility

Contact Comau

You can get in touch with our Sales Area, by entering your contact information.