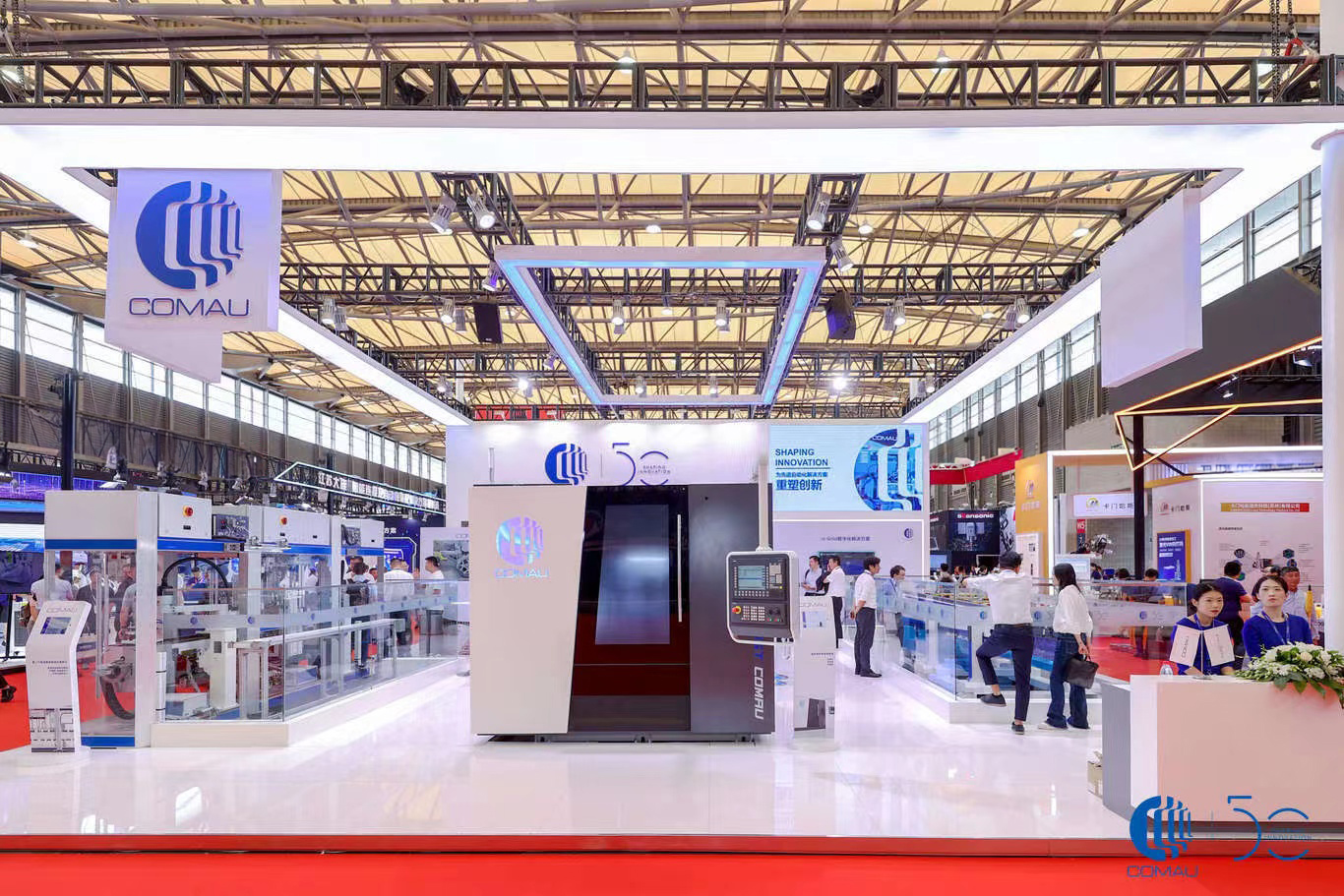

COMAU IS SHAPING INNOVATION WITH ADVANCED AUTOMATION SOLUTIONS AND E-MOBILITY TECHNOLOGY AT AMTS 2023 IN CHINA

• Leveraging 50 years of experience at a global level in Automotive, Comau is driving industry transformation with innovative advanced automation solutions, based on robotics and digitalization, for e-mobility and many other markets

• Demonstrating its highly regarded competency in advanced automation, Comau is showcasing various innovative solutions for the automotive industry

• Comau will unveil its new e-mobility Hairpin Assembly Technology solution for e-motors, which ensures higher efficiency, flexibility and precision in production line design to help e-vehicle manufacturers reduce costs and improve performance

Shanghai, July 5, 2023

At the 18th Shanghai International Automotive Manufacturing Technology & Materials Exhibition (hereinafter referred to as “AMTS”) held July 5 to 8, Comau will present its latest comprehensive automated solutions for the automotive manufacturing field. Under the theme “Shaping Innovation: Advanced Automation Solutions”, Comau will showcase innovative technologies based on robotics and digitalization, applicable in the area of e-mobility as well as in many other different markets.

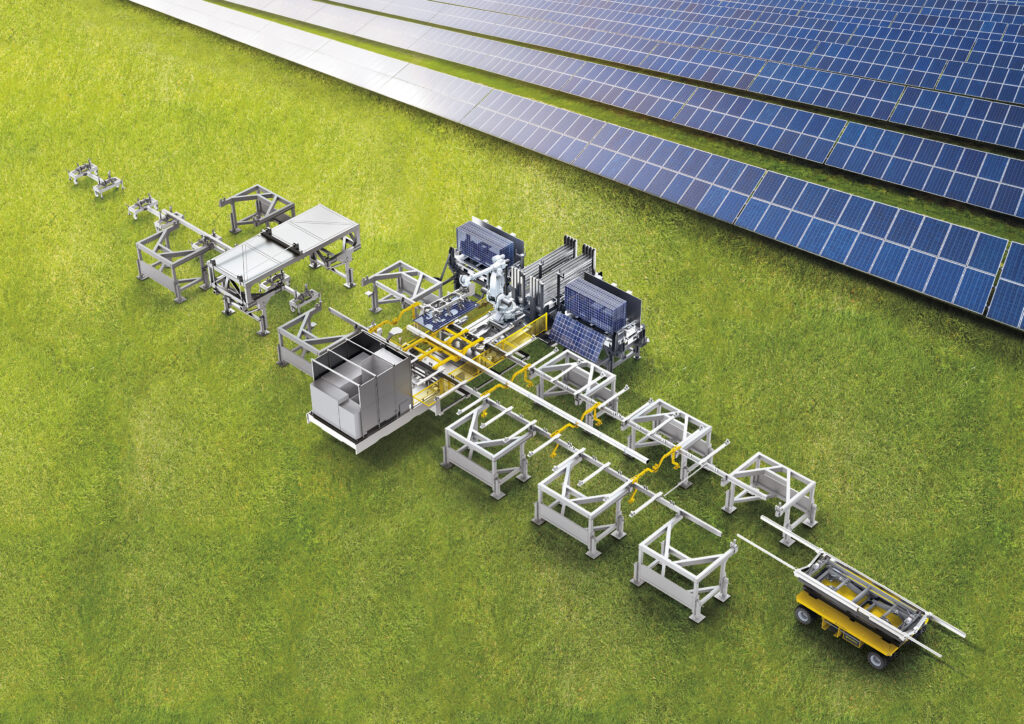

At AMTS 2023, Comau will preview its new Hairpin assembly technology solution for e-motors. The new solution overcomes the limitations of traditional circular coil winding and offers customers a more efficient, flexible and precise production line design. It not only contributes to the development of lightweight vehicles, but also enhances the potential for energy savings, helping companies reduce costs and improve efficiency.

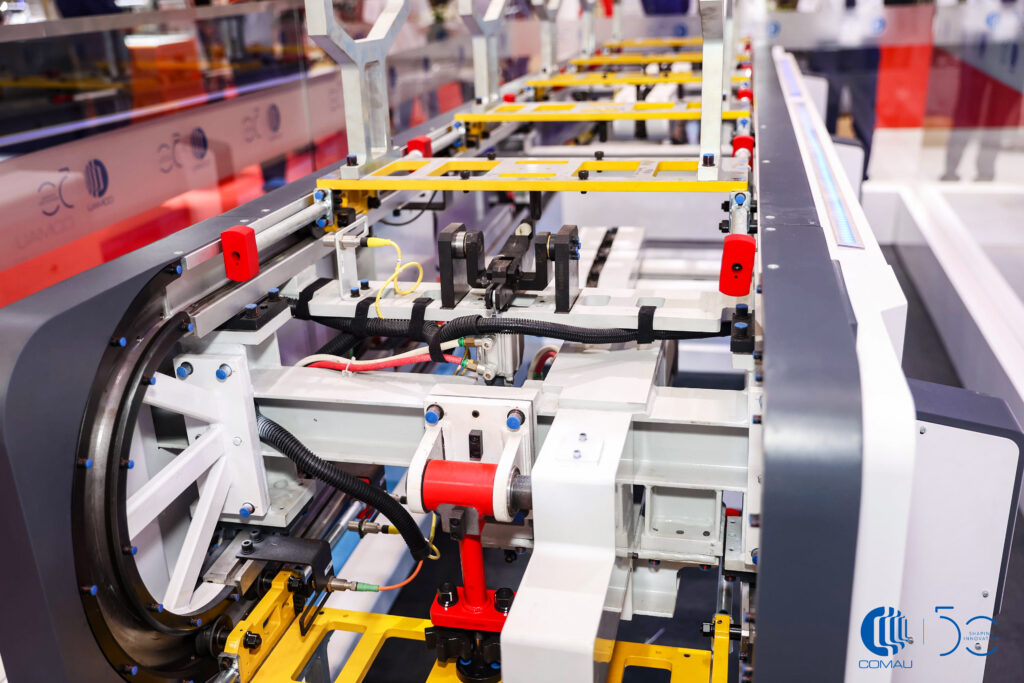

The exhibited second-generation high-speed conveyor for battery modules enables precise high-volume prismatic and pouch electric cell processing, greatly enhancing the performance and safety of battery systems. It also achieves a flexible and high-productivity systems design in compact layouts.

On display at AMTS also in.Grid, a proprietary IoT solution for data collection and line/cell//product/process monitoring. The platform combines digital and physical worlds through sensorization, data analysis and real-time monitoring of equipment, systems and production lines. in.Grid facilitates the acquisition and exchange of data by interconnecting Comau and non-Comau manufacturing machinery and equipment to enable process/technology data monitoring and telemetry for predictive maintenance and productivity goals. By joining communications, data control and analytics within a single, easy-to-use platform, in.Grid helps leverage the power of intelligent automation in a cost-effective and highly efficient manner.

Long proven, Comau´s Gravity APC, an innovative accumulating pallet conveyor, uses a pneumatic system to increase the potential energy of materials, achieving efficient and flexible material transport between two points using gravity and walking wheels, without the need for a motor drive.

With 50 years of experience at a global level in industrial automation and a deep understanding of the manufacturing process, Comau is a leader in providing the best-in-class production systems for Automotive. This experience has allowed the company to be perfectly equipped to address the transformation required by e-Mobility. Indeed, the company has already proven its strong competencies for e-mobility in various projects for multiple OEM´s in China as well as battery manufacturers in other regions.

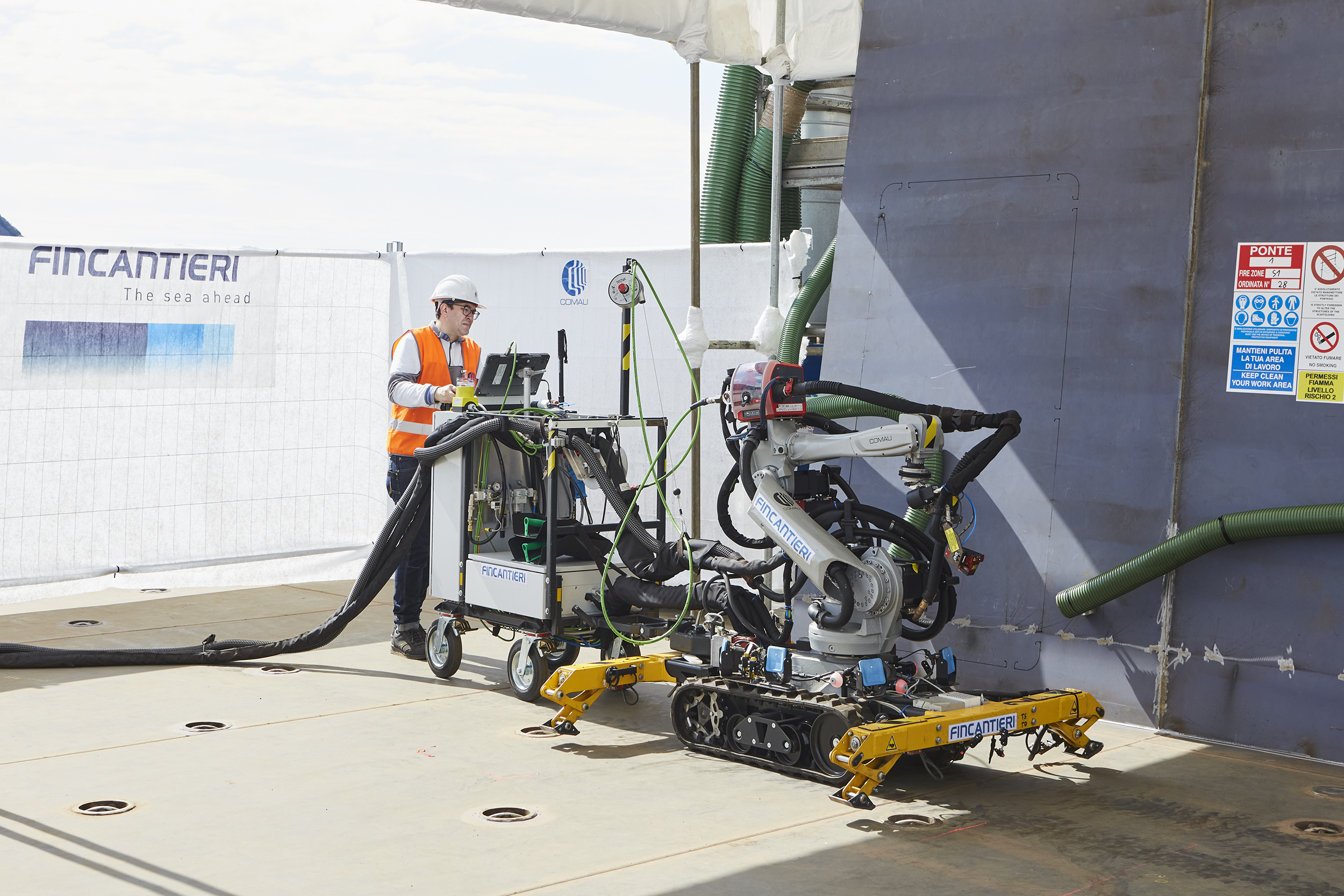

From a technology standpoint, Comau covers all phases of the battery manufacturing cycle (for prismatic and pouch formations, passing from complete packs to individual elements, including modules and cells) and electric motors. Thanks to its focus on innovation the company is also working on next-generation battery technologies (e.g., solid state batteries), robotic battery dismantling and recycling solution (Flex BD project). In the hydrogen sector, Comau is developing solutions for fuel cells and electrolyzer production.

Specifically, in China, Comau is collaborating with Shanghai Hydrogen Propulsion Technology, a leading hydrogen fuel cell company, to provide an advanced production line for its hydrogen fuel cell stack. Similarly, and among other projects, the company is pursuing opportunities to design, produce and sell hydrogen solutions in other regions.

Comau is committed to pursuing sustainable operations, both as a company and through the products and services it provides, in a customer centric perspective, helping them work more efficiently, use fewer resources and increase workplace well-being as key pillars of its commitment to sustainability.

The use of in.Grid interactive IOT platform, which allows real-time, 24/7 local and remote monitoring of technological data and telemetry ensures both resource and process optimization during deployment and operations, just to name an example.

“2023 is a special year for Comau. It marks the 50th anniversary, 26 of which marked by a deep-rooted local presence in China. During this period, Comau is shaping innovation by consolidating its long standing expertise to develop increasingly diversified technologies, based on advanced robotics and digitalization, which can make production processes in e-Mobility and many other sectors increasingly efficient and sustainable.”

Jeff Yuan, Comau Head of Countries Cluster APAC

Downloads

About Comau

Comau, a Stellantis company, is a worldwide leader in delivering sustainable advanced automation solutions. With 50 years of experience and a global presence, Comau is helping companies of all sizes in almost any industry leverage the benefits of automation.

Backed by a continuous commitment to designing and developing innovative and easy to use technologies, its portfolio includes products and systems for vehicle manufacturing, with a strong presence in e-Mobility, as well as advanced robotics and digital solutions to address rapidly growing markets in industrial sectors.

The company’s offering also extends to project management and consultancy. Through the training activities organized by its Academy, Comau is committed to advancing the technical and

managerial knowledge necessary to face the challenges related to automation and

leverage the opportunities of a constantly changing marketplace.

Headquartered in Turin, Italy, Comau has an international network of 5 innovation centers, 5 digital hubs, and 12 manufacturing plants that span 13 countries and employ 3,700 people. Together with its wide network of distributors and partners, the company is able to respond quickly to the needs of its customers, no matter where they are located throughout the world.

Contact Comau

You can get in touch with our Press Office and Media area,

by entering your contact information.