THE FIRST ROBOTIZED MOBILE SOLUTION FOR SHIPBUILDING

The two companies have also strengthened their collaboration by signing a renewed Letter of Intent

• Unveiling the first result of the collaboration, Comau and Fincantieri present MR4WELD, a unique, mobile robotic welding solution, at Automatica 2023

• The two Italian companies, leaders in their respective markets, who started collaborating in 2021, continue their on-going relationship with the signing of a renewed agreement that includes the development of new robotic products and high-technology solutions

• Activities included in the agreement are based on the joint objective to apply technology, digitalization and innovation to develop mobile robotized solutions for unstructured environments aimed to increase both production performance and worker well-being

• Designed and deployed to weld steel structures during the vessels’ building stage in the shipyards, the inherently flexible solution can be easily reconfigured to address other application areas and industries

Trieste and Grugliasco (Turin), June 28, 2023

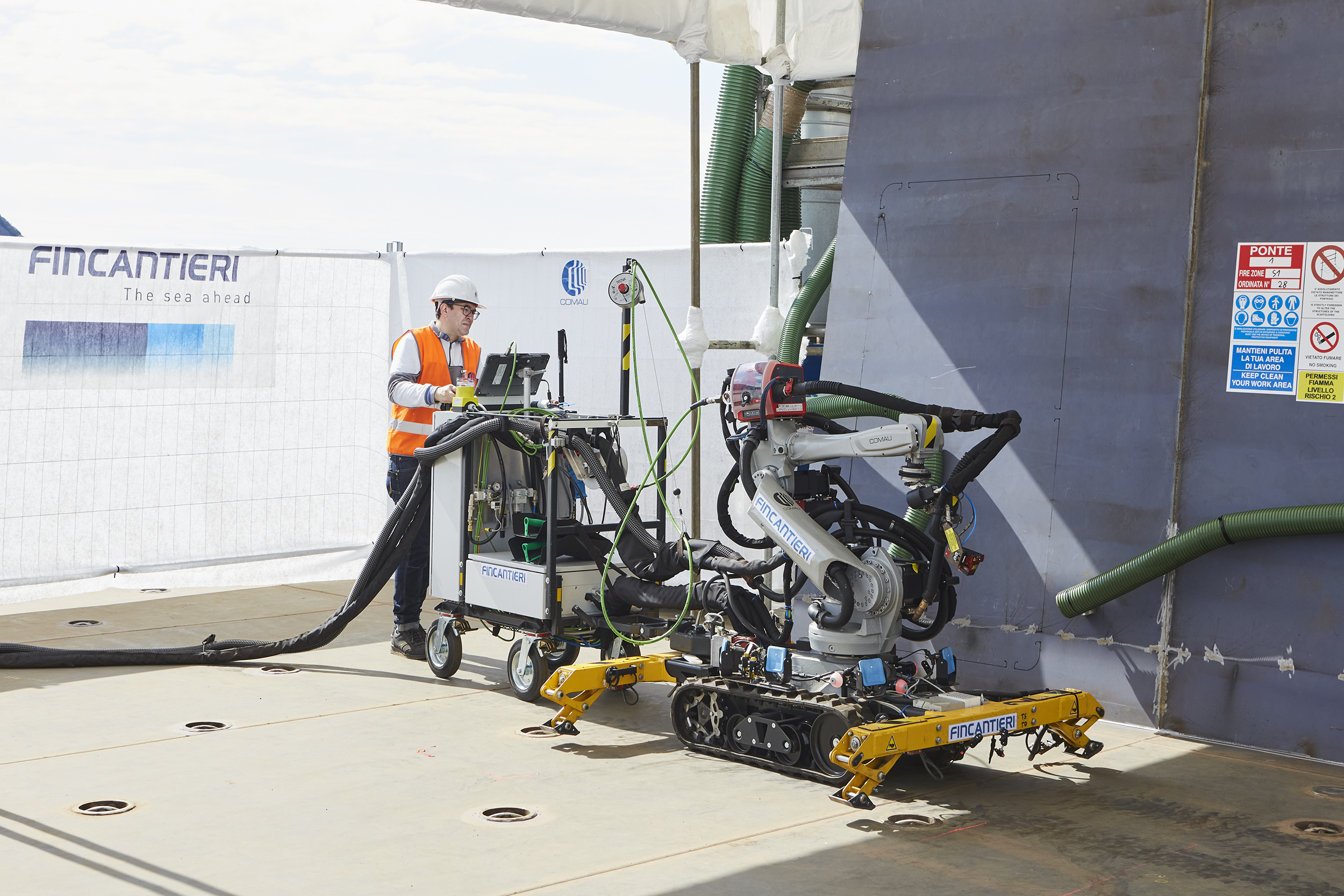

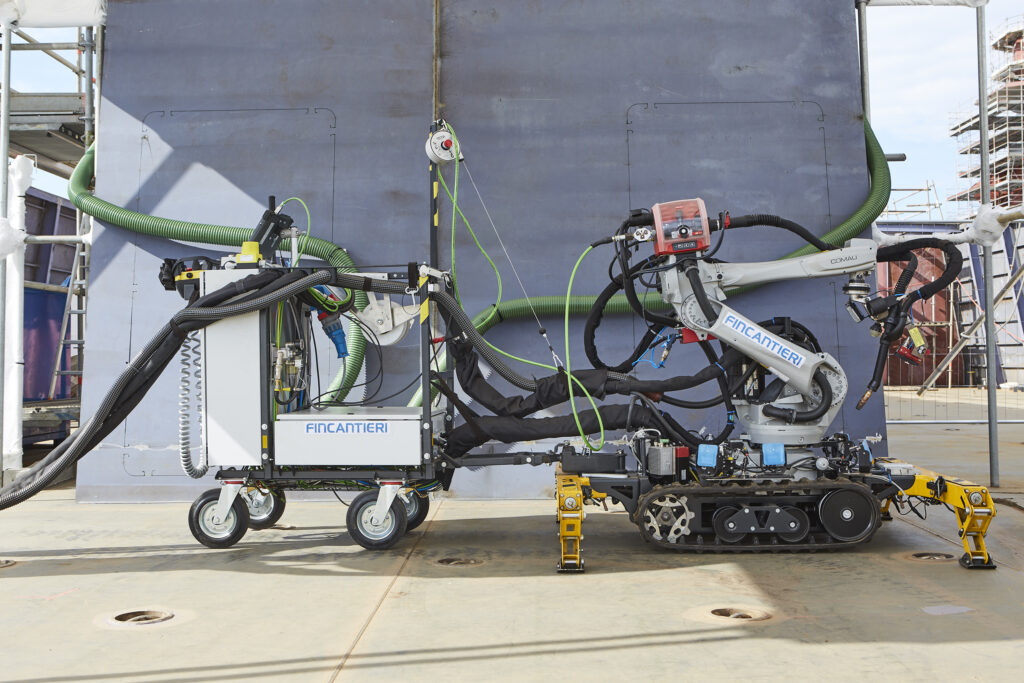

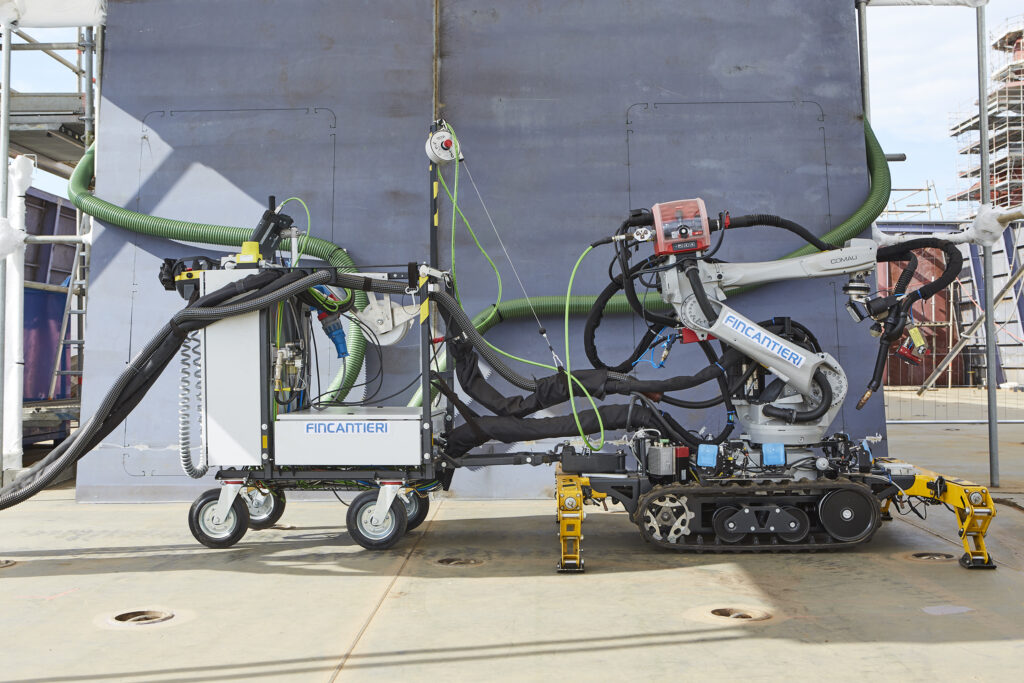

Comau and Fincantieri, two Italian world leaders in their respective markets, present the first result of their joint collaboration at Automatica: MR4Weld (Mobile Robot for Welding) mobile robot, an innovative outdoor automation solution to improve quality, performance and well-being during labor-intensive welding activities.

The companies have also renewed their strategic agreement to apply technology, digitalization, and innovation within cutting-edge, mobile robotic solutions that will increase production speed and worker well-being, by automating traditionally manual processes.

Having first signed a letter of intent in 2021, which was aimed at developing robotized steel welding solution prototypes and the resulting construction of a series of machines – after successful completion of production tests of the prototypes which are currently undergoing, Comau CEO, Pietro Gorlier, and Fincantieri CEO, Pierroberto Folgiero, have signed a renewed agreement which foresees the development of additional mobile robotized machines and solutions for unstructured environments.

Automation beyond the factory floor

Considered a new paradigm in bringing automation beyond the factory floor, the MR4Weld mobile robot is being tested and will be subsequently used within Fincantieri shipyards to autonomously weld steel structures, with a possible 3-fold increase compared to a manual process. It features a high-payload, 6-axis articulated robot fitted with a welding torch that is installed on a tracked undercarriage and equipped with an integrated vision system to autonomously identify welding joints. More importantly, it guarantees better welding quality while reducing ergonomic risks, helping the transformation of the shipbuilding production process by ensuring greater flexibility and improved safety in addition to lower overall costs.

Designed to be able to move in any environment and to collaborate with workers, MR4Weld can be easily managed by a single operator during the transfer and welding activities. The system also employs digital tools to collect welding and production data that can be used to record the welded joints. Since MR4Weld is in complete compliance with current safety regulations, it can be used without fences on each of the multiple decks that a vessel is made up of. Fincantieri and Comau have jointly filed a European patent application for specific MR4Weld technological features. The cutting-edge solution can also be seamlessly integrated within Comau’s digital infrastructure, further safeguarding the robotic system’s productivity and profitability.

Advanced and mobile robotics

As part of the renewed collaboration, the companies will develop advanced and mobile robotics to automate other repetitive activities of the shipbuilding processes including those characterized by vertical and non-linear surfaces as well as unstructured environments, in addition to the testing of Comau’s exoskeletons for further improving the operators’ ergonomic conditions and well-being.

Fincantieri will also work with Comau to strengthen and upgrade the technical skills of its operators in terms of using and programming the robotized mobile systems, by adapting to the shipbuilding operators’ dedicated advanced training formats, which are already developed by Comau. In fact, implementing automated solutions for highly repetitive and non-high value-added production activities represents one of the pillars of Fincantieri’s strategy.

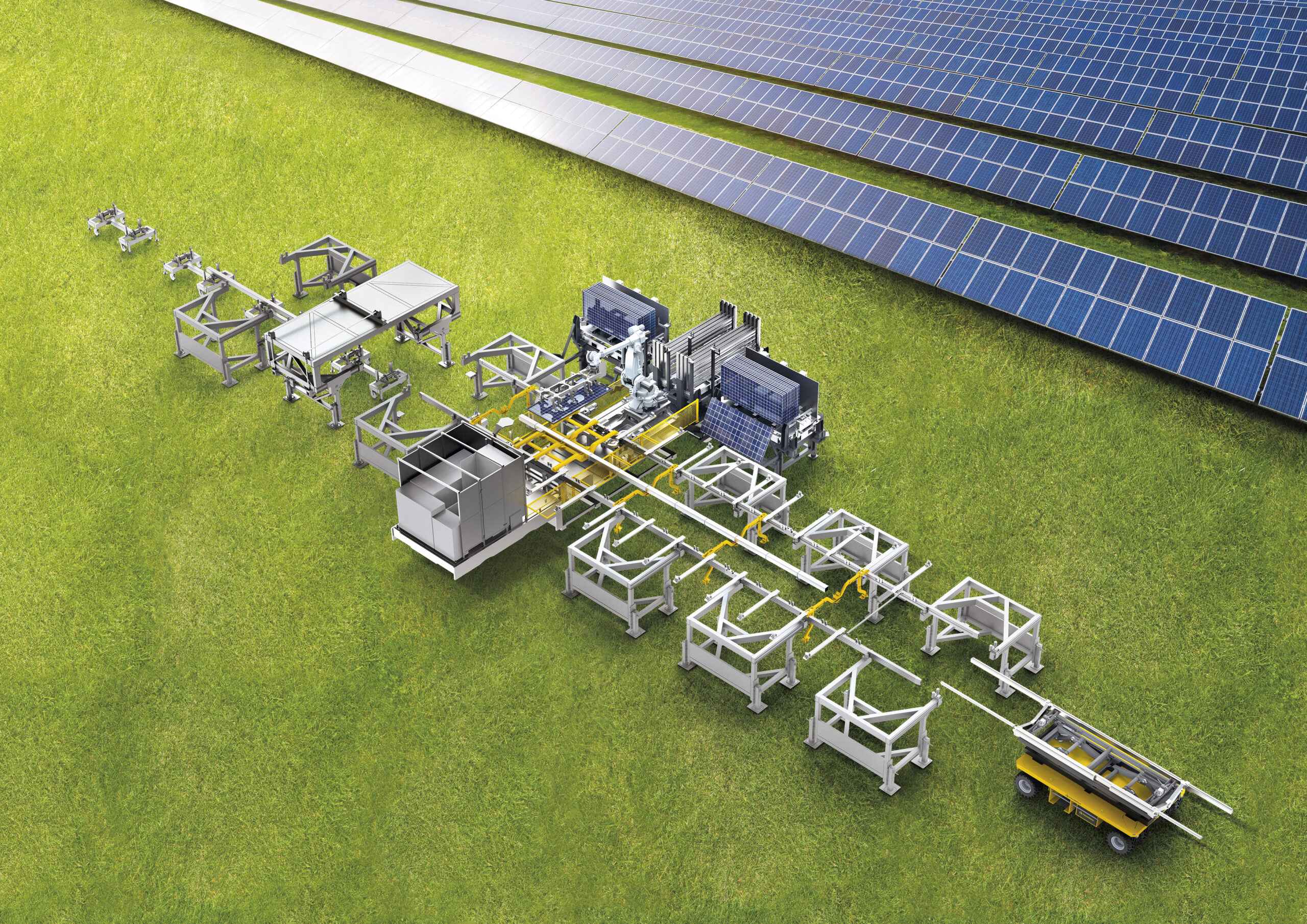

Expanding into new segments

Comau will also take yet another step toward differentiating its core business and expanding into new segments beyond the factory floor. Furthermore, the companies will begin industrializing their unique MR4Weld robotics solution which can be applied not only to the shipbuilding industry but also for industries that require the production of large steel infrastructures, among others. Within the LoI, the companies will study and evaluate the ways and relevant agreements for further facilitating the prompt development of the identified technological solutions.

Groundbreaking robotized mobile systems

“In addition to the opportunity to work with a leader such as Fincantieri, and explore groundbreaking robotized mobile systems for unstructured environments, the extension of our collaboration reflects Comau’s determination to deliver cutting-edge, highly flexible solutions for complex production scenarios. We also believe the significant market potential for the MR4Weld mobile robot extends beyond shipbuilding. Especially given that the mobile robotics market is estimated to see a 5-year CAGR of 15% (2022 to 2027) according to internal estimates and supporting market research”.

Pietro Gorlier, CEO of Comau

Source: Statzon, IFR World Robotics 2022 – Service Robots

Pursuit of excellence

“MR4Weld is a project that meets multiple directions of our development: automation and digitization, two driving forces of our business plan as well as the corporate responsibility, which finds an answer in the achievement of five of the UN sustainable development goals, also with reference to safety and training. The partnership with Comau has produced a unicum in our sector, a result of great industrial value which confirms Fincantieri’s commitment to the pursuit of excellence”.

Pierroberto Folgiero, CEO of Fincantieri

Downloads

About Fincantieri

Fincantieri is one of the world’s largest shipbuilding groups, the only one active in all high-tech marine industry sectors. It is leader in the construction and transformation of cruise, naval and oil & gas and wind offshore vessels, as well as in the production of systems and component equipment, after-sales services and marine interiors solutions. Thanks to the expertise developed in the management of complex projects, the Group boasts first-class references in infrastructures, and is a reference player in digital technologies and cybersecurity, electronics and advanced systems.

With over 230 years of history and more than 7,000 ships built, Fincantieri maintains its know-how, expertise and management centres in Italy, here employing 10,000 workers and creating around 90,000 jobs, which double worldwide thanks to a production network of 18 shipyards operating in four continents and with almost 21,000 employees.

Press Office

Tel. +39 040 3192473

press.office@fincantieri.it

Investor Relations

Tel. +39 040 3192111

investor.relations@fincantieri.it

About Comau

Comau, a Stellantis company, is a worldwide leader in delivering sustainable advanced automation solutions. With 50 years of experience and a global presence, Comau is helping companies of all sizes in almost any industry leverage the benefits of automation.

Backed by a continuous commitment to designing and developing innovative and easy to use technologies, its portfolio includes products and systems for vehicle manufacturing, with a strong presence in e-Mobility, as well as advanced robotics and digital solutions to address rapidly growing markets in industrial sectors.

The company’s offering also extends to project management and consultancy. Through the training activities organized by its Academy, Comau is committed to advancing the technical and

managerial knowledge necessary to face the challenges related to automation and

leverage the opportunities of a constantly changing marketplace.

Headquartered in Turin, Italy, Comau has an international network of 5 innovation centers, 5 digital hubs, and 12 manufacturing plants that span 13 countries and employ 3,700 people. Together with its wide network of distributors and partners, the company is able to respond quickly to the needs of its customers, no matter where they are located throughout the world.

Contact Comau

You can get in touch with our Press Office and Media area, by entering your contact information.