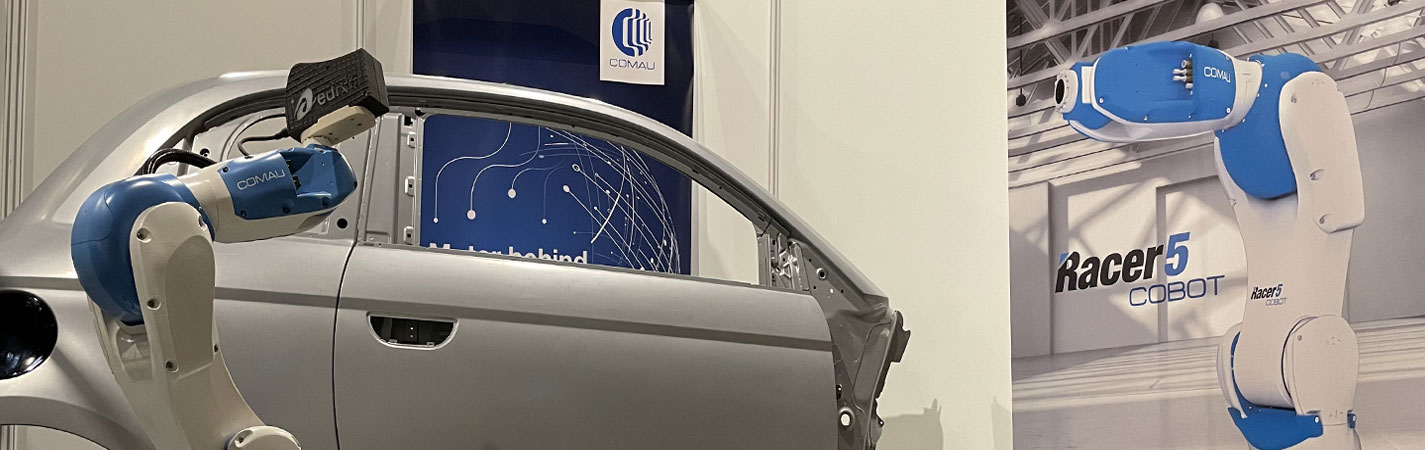

Turin, October 15, 2021 – Comau has positively responded to the Stellantis Factory Booster Day challenge by developing a fully automated gap and flush verification system to measure potential defects on multiple, dissimilar parts while the car is moving along the final assembly conveyor. Featuring a RACER-5 collaborative robot integrated with an Edixia vision system, it looks at alignment points along the entire car body, collects the data and monitors trend quality.

The innovative solution, which can easily be applied to other applications within the automotive and general industry segments, thus automates a typically manual procedure while gaining an additional level of quality control. Furthermore, the increasing use of standardized building blocks, such as the cobot, state-of-the-art vision technology and control software, has enabled Comau to design the tailor-made project to achieve an estimated payback of 12 months.

Comau unveiled its gap and flush verification solution during the Stellantis Factory Booster Day, held at the Forum Armand Peugeot, in Poissy, France, on October 13. Reflecting the company’s steadfast commitment to innovation for the automotive industry, the winning solution is based upon a high-performance collaborative robot that allows operators to safely intervene if needed. This further reduces cycle time as well as rework caused by nonconformity.