- Innovative solutions and products for electrification, robotics, smart manufacturing and human-machine collaboration developed according to Comau’s HUMANufacturing approach

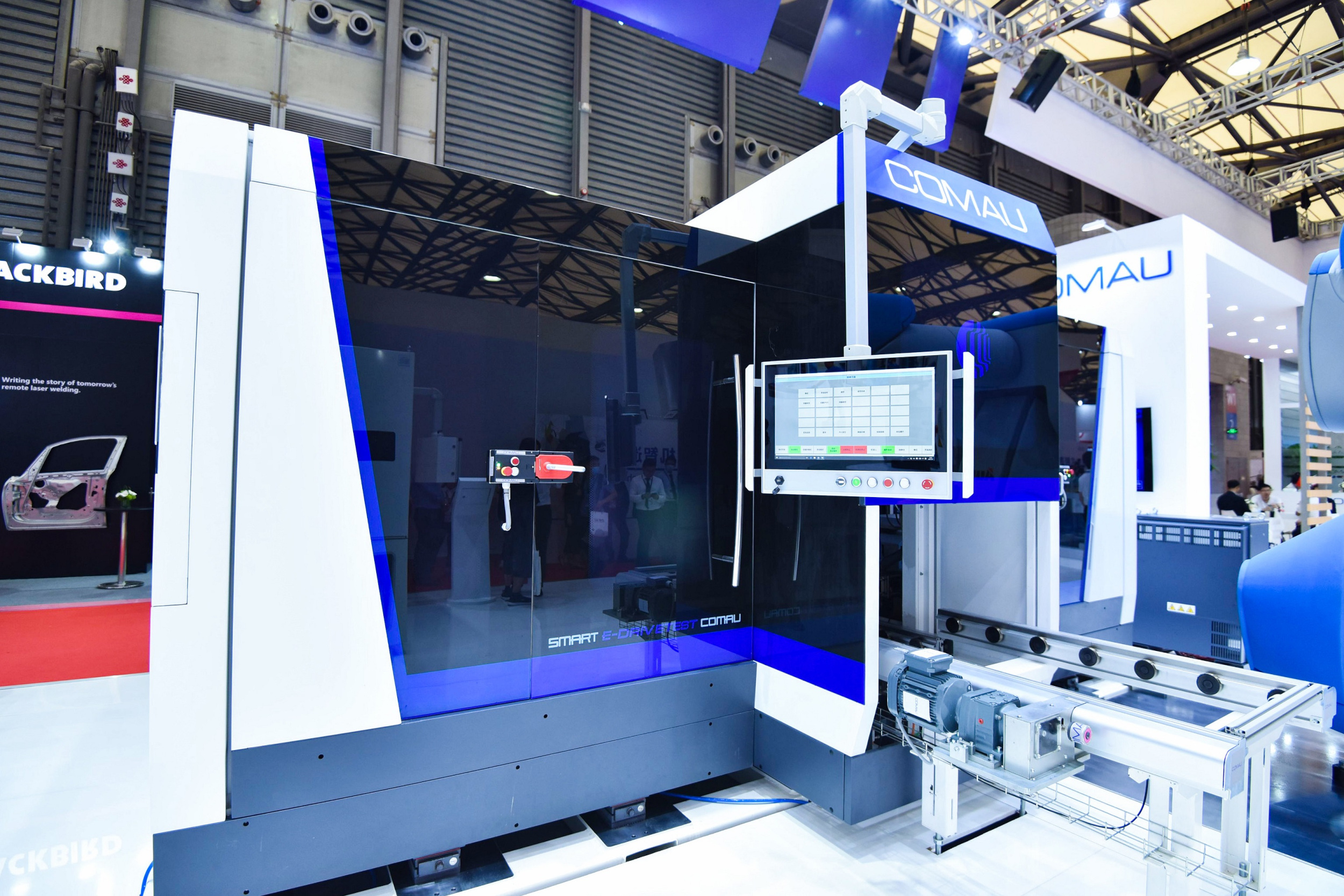

- Smart E-Drive Test Bench combines standardization, flexibility and reconfiguration

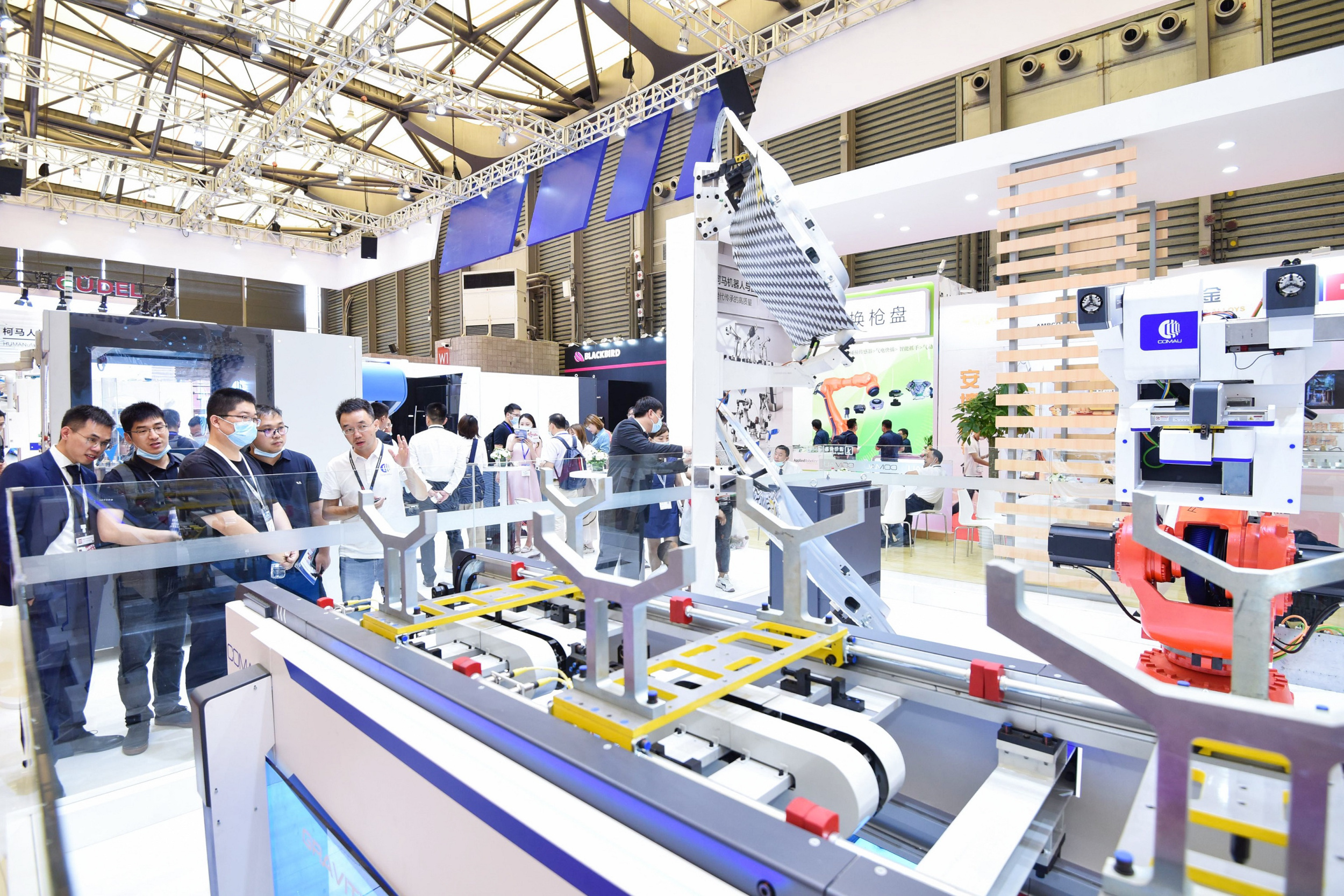

- Smart High-Speed Conveyor enables flexible, high-productivity systems for battery assembly

- Universal Gripper ensures the flexibility of welding fixtures, which can help customers save investment costs in multiple dimensions.

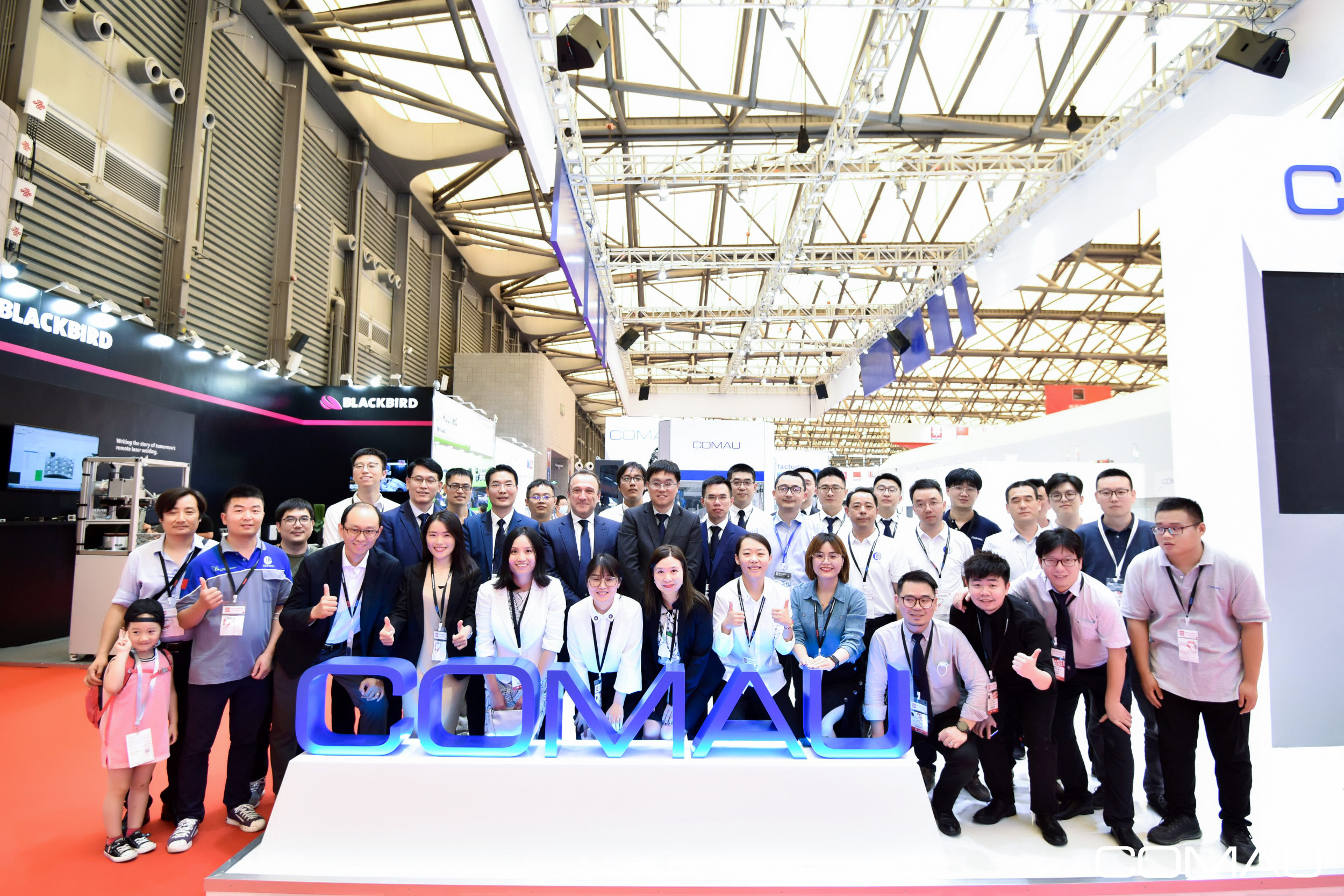

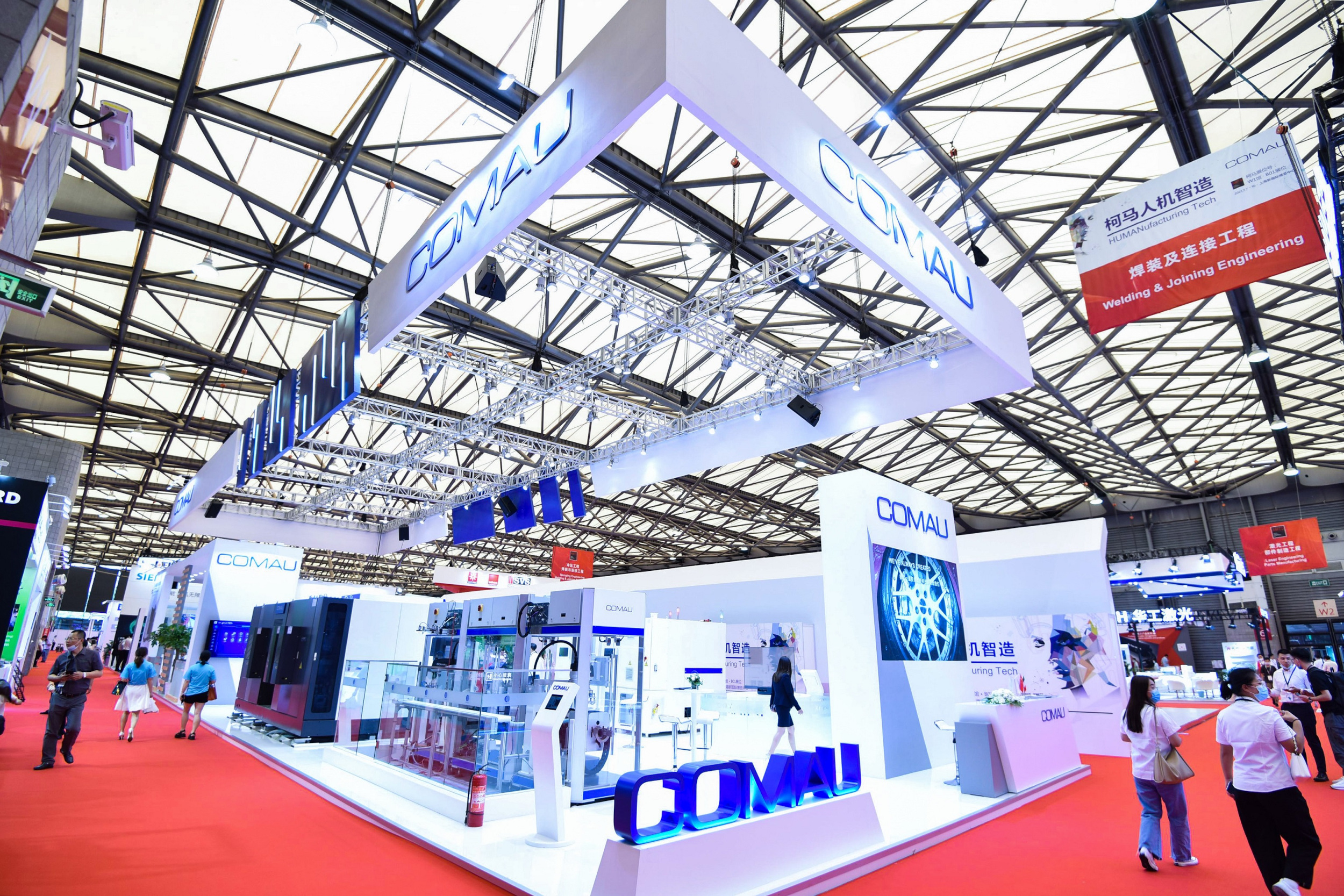

Shanghai, July 7, 2021 – The 16th Shanghai International Automotive Manufacturing Technology and Materials Show (referred to as ‘AMTS’) officially starts today at Shanghai New International Expo Center. With innovation as the driving force, Comau continues to evolve its electrification, robotics, smart manufacturing and human-machine collaboration offer to meet the rapid development of the Chinese automotive and non-automotive markets, in addition to the needs of local customers, by introducing innovative products and solutions.

Gaetano Cantalupo, Global Head of Comau Customer Operations and Managing Director of Comau China said, “As a global leader in advanced industrial automation, Comau benefits from the winning combination of strong technological know-how and long-term experience in providing powertrain assembly, machining and body assembly solutions for both traditional and electric vehicles. For the last 24 years we have been nurturing meaningful partnerships in China aimed at boosting the automation industry’s growth. We now have the largest number of new products on display since Comau began participating in AMTS, and believe our local customers will enjoy gaining a deeper understanding of our system solutions that are customized for their specific needs.”

Focusing on electric drive and battery testing and assembly, Comau’s electrification solutions enable the development of the electric vehicle industry

In the field of electric vehicles, Comau integrates standardized, modular, scalable and flexible solutions to meet the latest requirements and challenges of the electric vehicle industry. Comau launches the new Smart E-Drive Test Bench at AMTS. As the key equipment for off-line inspection of e-motor assembly lines, it can provide customers with full-featured testing including electrical performance testing, dynamic testing and NVH (Noise, Vibration, Harshness) testing and analysis.

Comau’s Second-Generation High-Speed Conveyor for battery modules is driven by linear motors and can be widely used for high-volume prismatic and pouch battery cell processing as well as electronic component assembly and testing. As such, it fully supports flexible, high-productivity systems even in compact layouts.

A new generation solution for laser welding based on BLUE BOX, a flexible technology platform independently developed by Comau Powertrain Assembly Segment is also on display. The Smart Laser Welding Station can be used in welding applications for high power density cylindrical core modules, which requires laser welding instead of bonding welding. Through the breakthrough of high-speed and high-density welding, the product connection performance and welding reliability are greatly improved. A new manufacturing path for the core process of manufacturing cylindrical battery packs for vehicles is realized.

The BLUE BOX platform was developed for electrification through the research, aggregation and refinement of product manufacturing processes by Comau. It has the advantage of electromechanical integration and is compatible with a variety of manufacturing processes such as assembly, tightening, gluing, welding, and testing. The similarity of different equipment configurations within the same platform, the commonality of core components, and the interchangeability of process equipment enable the standardization of non-standard assembly lines, thus facilitating the design development and production changeover of equipment, significantly speeding up the delivery of production lines, achieving rapid mass production and helping customers reduce product lifecycle costs and increase production flexibility.

Based on global technology, supported by local R&D, Comau is helping China’s automotive manufacturing industry to develop automation and intelligence

China’s automotive manufacturing industry is achieving an increasingly high degree of automation. The Accumulating Pallet Conveyor, a gravity APC transfer system exhibited by Comau, is a confined space conveyor. Committed to the concepts of “Lean R&D” and “Lean Production”, Comau China has developed a new product concept that is unlike other APCs on the market. Traditional APCs are mechanical structures with the motor as the drive unit and the chain as the power transmission medium. Comau’s gravity APC system can transfer workpieces by gravity without additional power, relying only on the workpiece’s own energy potential. The innovative mechanism has obtained several invention and utility model patents.

In addition, Comau demonstrates its Universal Gripper at AMTS, which is suitable for any three-hole positioning part, especially for door parts. Furthermore, the gripping point of the gripper adapts to the changing position of the positioning holes. By integrating grippers and robots into a single unit, Comau has truly realized the flexibility of welding fixtures, which can help customers save investment costs in multiple dimensions.

Setting the benchmark for human-machine collaboration in an Industry 4.0 perspective

Human-machine collaboration is at the heart of Comau’s “HUMANufacturing” approach. Comau has always been committed to creating a complete and safe collaborative system for manufacturing operations that address the need to assist workers with innovative technologies in operations that require greater speed, intensity and repeatability.

Two innovations in human-machine collaboration are being presented for the first time in the Chinese market. AURA, which is approximately three meters tall and weighing approximately three tons, is a collaborative industrial robot that assists workers in their jobs. Without any enclosure structure, AURA can work at the same station as the operator and is the only collaborative robot on the market with loads of up to 170 kg. The other innovative product is MATE-XT, a new generation of wearable muscle-assisted exoskeleton with a lightweight carbon fiber structure and intuitive adjustment system that is designed for both indoor or outdoor use.

With roots in the Chinese market that span 24 years and are built upon strong global support and sustainable localized development, Comau China has established consolidated partnerships with many international and local customers, and has helped many companies improve their productivity and quality by providing advanced automation technologies into all areas of industrial manufacturing.