A Hybrid Human Robot Collaborative Station able to automate the quality and functional testing actions performed within the white goods industry: this is the innovative result achieved by the work team of the European project Rubic, in which Comau has participated together with Whirlpool Italia and the Greek partners CASP- software and consulting company – and the University of Patras’ Laboratory for Manufacturing Systems & Automation (LMS). The project, which was completed in December 2020, was conducted as part of a Call for Proposals launched in 2019 by EIT Manufacturing, the EU Community created to connect Europe’s main manufacturing players.

In synergy with the other companies, Comau provided its know-how in the field of industrial automation for the manufacturing sector, as well as its latest technologies for collaborative robotics and Human Machine Interfaces (HMIs). In particular, the Rubic station features the new collaborative robot Comau RACER-5-0.80 (Racer-5 COBOT) whose safety strategies and equipment allow the cell to work without barriers, integrated with intuitive interfaces for safe human-robot cooperation, a smart vision system for inspection activities and a flexible communication architecture.

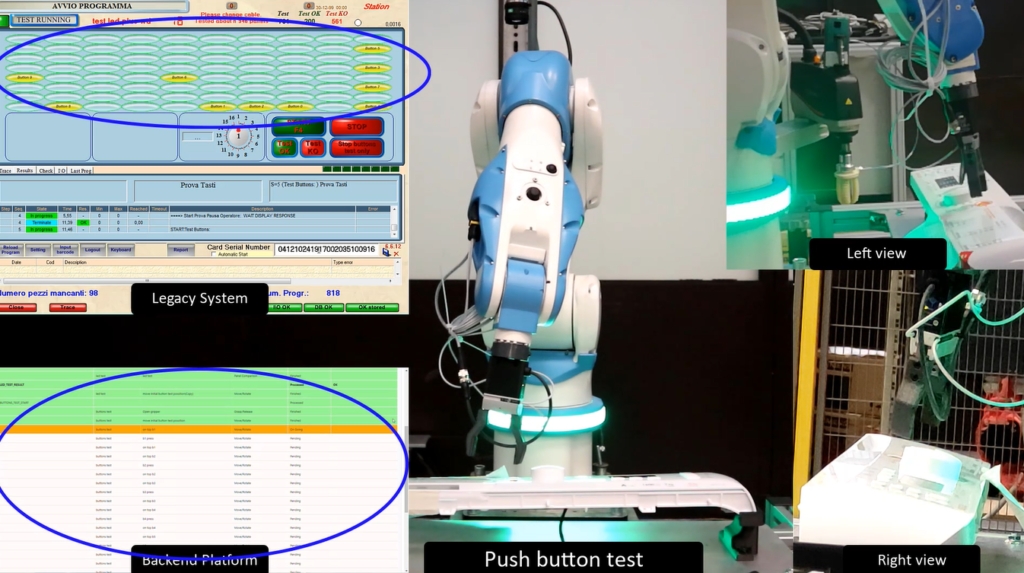

The innovation proposed by this cell derives from the combination of high-end technologies that exploit the combined strength of the robot and human cognitive abilities. The main objective of this cell is to help operators perform quality assessments on parts or components, thus avoiding that defective products reach the final customer. In particular, the novel system implemented has been applied for the automatic end of line testing of washing machines panels: the Cobot has been used to push the buttons and rotate the knob of the panel, testing all the functionalities and assessing the results, in connections with the software platform. Different models of washing machines panels have been taken into account with a specific focus on tools for easy programing of new task (also for not skilled operator).

The advantages are many: the collaborative cell relieves operators from carrying out repeatable and tiring operations, letting them focus on tasks with greater added value, such as vision and preparation of the production cell. In addition, automating quality control operations facilitates data registration by keeping track of all information for each part. Thanks to this collaborative automation solution, which can be replicated in other sectors and for different applications, it is possible to increase the flexibility of industrial processes, improve product quality and increase the efficiency of collaborative task sequence.

Launched in March 2021, Racer-5 COBOT is a 6-axis articulated robot that can work at an industrial speed of up to 6 m/s. With a 5 kg payload and 809 mm reach, it ensures optimal industrial efficiency while granting the added benefit of safe, barrier-free operations. Furthermore, the cobot can instantly switch from a collaborative mode to full speed when operators are not around, letting its 0.03 mm repeatability and advanced movement fluidity deliver unmatched production rates.

For more information, please send an email to alfio.minissale@comau.com.

Comau – https://www.comau.com/en

CASP – https://www.casp.gr/

LMS (Patras university) – https://lms.mech.upatras.gr/

WHIRLPOOL – https://www.whirlpool.it/