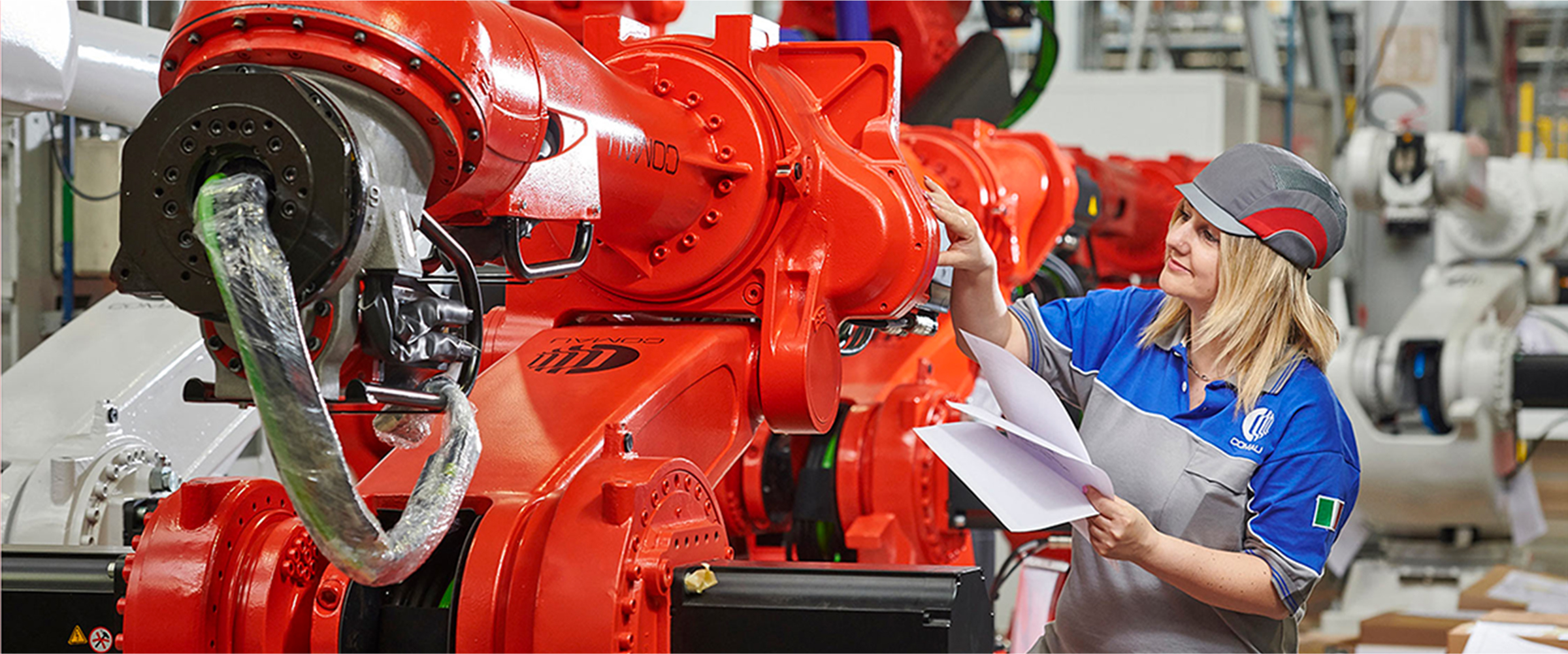

The COnsorzio MAcchine Utensili

Formed in 1973 by several small Torino-based companies that were providing machinery to the Fiat Group. From the very beginning, Comau has accepted challenging projects that seemed impossible for others.

1970

Comau began as the Consorzio Macchine Utensili.

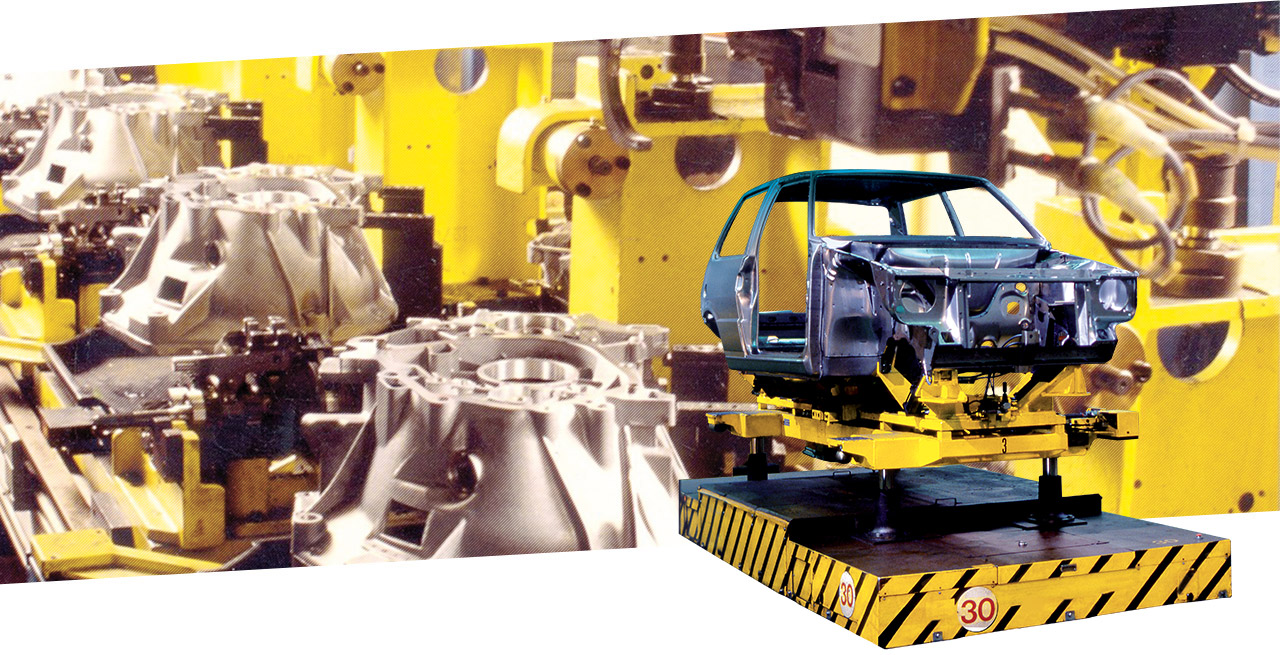

It is the sum of experiences started back in 1973. From ‘Robogate’ the innovative industrial robotized system to the first hydraulic robot.

1984 – 1993

We started a new era with the first FMS – Flexible Manufacturing Systems. Creation of high speed machining technologies and the first laser robot.

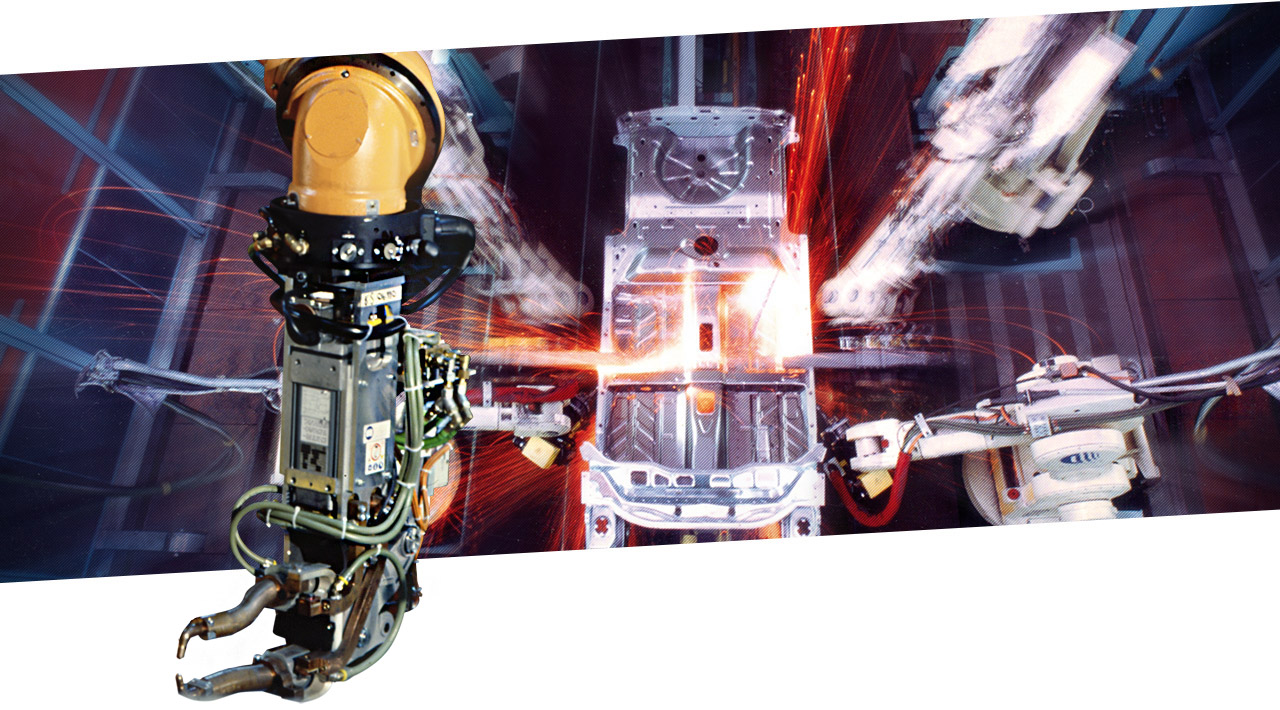

1995 – 2005

We went global, expanding business in Europe, North America, South America and Asia.

Creation of Smartdrive Machining Centers, First Open Robogate framing systems.

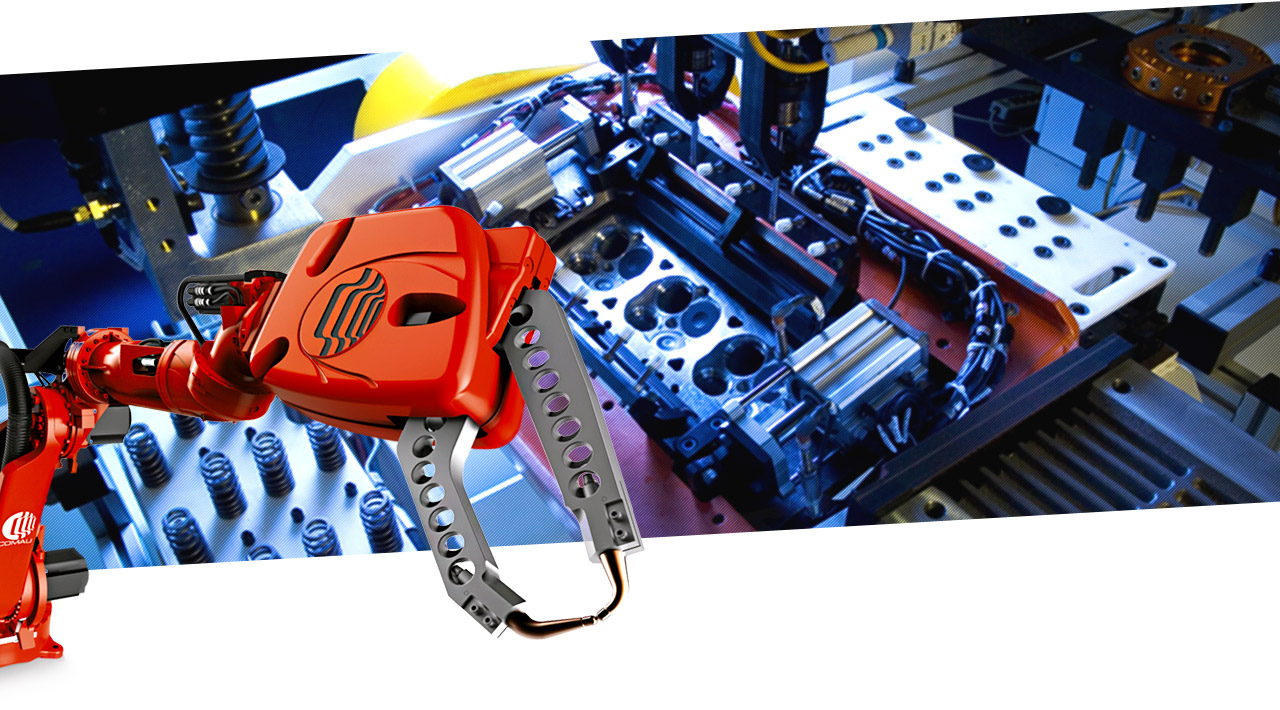

2006 – 2016

Driving innovation in Automation & Manufacturing with the breakthrough technologies like butterfly systems for chassis welding.

2017 – 2022

We designed a new Electrification path to start our e-mobility journey in an ongoing race to the new digital world.

2023 onwards

Advanced automation solutions and new initiatives for sustainability. With 50 years of strong heritage, we are ready to keep on building a bright future.

Learn more about Comau

Sustainability

Comau’s ongoing push for innovation has naturally led it to adopt and create sustainable solutions and technologies, both for its own operations and those of its customers.

Corporate Governance

Comau Group companies are strongly committed to conducting their activities in compliance, respecting the highest standards of ethics and integrity.

Quality

Comau’s Quality Management System conforms to the latest international standards. Comau’s Quality Management System conforms to the latest international standards.